HYDROS 101

HYDROS 101

Whether you have been a fan for decades or are just learning about the sport of Unlimited Hydroplane racing, we want to help you learn about all facets of our sport – from a basic explanation of the races so you know what “heats” are and how to keep score, up to the intricacies of the Lycoming T-55 L7 gas turbine & Allison V-12 engines that power our boats and the aerodynamic forces that put the “plane” in “hydroplane”. It’s all here!

H1 UNLIMITED – THE SANCTIONING BODY

H1 Unlimited is the sanctioning body for the sport of Unlimited Hydroplane Racing in the Unites States. As a member of the APBA (American Powerboat Racing Association), we establish the rules that govern our races, the qualifications of the drivers, boats and the courses we run on. We also supply the personnel and equipment to put on the race at each venue, from the rescue crew to the media team to the tech personnel that insure everyone plays fair.

All of the members of the H1 Unlimited team are volunteers and all are long-term veterans of the sport, beginning as racers, crew, media or just plain fans. Most of our volunteers have been around boat racing for decades, involved at every level imaginable.

If you are at one of our races and want to learn more about the sport or volunteer your time, be sure to flag down a “Blue Shirt”!

The H1 Unlimited staff are volunteers that love the sport and it’s history and are working very hard to insure its future. From the Board of Directors to the Referees, Timing and Scoring, PA Announcers, Media and Technical staff, we all enjoy bringing the fastest boats on the water to your lakes, rivers and bays every year! Thanks for coming out to see races!

Meet the H1 Unlimited 2024 Staff:

H1 UNLIMITED BOARD OF DIRECTORS:

Mike Denslow – Chairman

Darrell Strong

Charlie Grooms

Shannon Raney

Kelly Stocklin

Brad Luce

REFEREES:

Jonathan Abbott – Head Referee

Matt Yarno – Assistant Referee

Sam Houghtaling – Assistant Referee

OPERATIONS:

Taryn Baze – Operations Director

Mark Mallory – Pit Boss

Jeff Shepherd – Assistant Pit Boss

Heidi Dunk-Vincent – Pit Operations

Don Agopsowicz – Truck Driver

Heidi Dunk-Vincent – Pit Operations

Suzy Shepherd – Risk Manager – Corral

Emily Raney – Credentials/Social Media

Ashley Raney – Credentials

RESCUE & MEDICAL:

Dave White – Director of Water Safety

Brannon Casler – Rescue

Dave Stering – Rescue

Joe Carrington – Rescue

Cathy Spry – Medical

TIMING & SCORING:

Jim Sharkey – Timer

Mary Compton – Timer

Nick Kish – Data

TECHNICAL:

Seph Parshall – Technical Referee

John Walters – Chief Inspector

Steve Compton – Tech Inspector

Brian Vincent – Tech Inspector

DRONES:

Lisa Courneya – Flight Director

Brian Montgomery – Drone Pilot

Dan Foard – Drone Pilot

MEDIA:

Tait Meyer – Live Stream

Jared Meyer – Live Stream

Matt Johnson – Live Stream

Chris Denslow – Photographer

Brad Luce – PA

Tana Morrisett – Media Liaison

Walt Ottenad – Website / Onboard Video / App

H1 Unlimited live-streams every session with boats on the water all season long on YouTube and Facebook.

Tait and Jared Meyer, brothers from Richland, WA established our current live streaming video program during the 2018 season and have refined it ever since. Beginning in 2024, our “Stat Man” – Nick Kish – took over the Livestream and included his wife, Rachel, cameramen Gio Belsito and Micky Washburn, and production assistant Tana Morisett to bring a full HD stream to any device that can receive it, anywhere in the world. We feel the livestream is the equal of any out there and brings you right to the shore for every one of our events!

At each race site, the crew sets up all of our gear the day before racing begins and tests the equipment, the connectivity and the final output so we are ready to bring our races to the world once testing starts. Every streaming session includes multiple camera angles from our on-shore cameras, drone cameras and remote cameras.

All sessions can be viewed on our YouTube channel and our Facebook page, as well as the H1 website – just click the “Video” menu item to watch all of our videos! Our livestream from San Diego is a great example of what you can expect from our streaming team:

In order to officiate our races, referees need to have an unobstructed view of the race course and all the boats on it.

In the past, this was accomplished by having a helicopter parked over each turn, with assistant referees in each one, keeping an eye on lane violations, overlap and other potential driving infractions. While helicopters were great for actually putting our referees eyes on the course, they were loud and rough, which made communication by the referees hard to hear and because having video evidence to review is critical to making the correct calls, helicopters were not ideal because the video our referees shot was EXTREMELY jerky due to the main rotor’s vibrations, as you can see in the following clip:

First discussed in 2014, H1 Unlimited began a feasibility study to determine if the helicopters could be replaced by drones, while still allowing referees to have the full picture of the racecourse as they would have from the helicopter.

Beginning in 2017, we started experimenting with drones that recorded video our referees could review after the heats were finished. The results were pretty extraordinary, but we could not rely on the video files to make decisions immediately, as the technology was not quite there to allow the real-time viewing that was required in order to shift completely away from the choppers.

In 2019, H1 Unlimited official Lisa Courneya established our Drone program that completely eliminated the use of helicopters by allowing our officials to see the view from each drone in real-time on monitors on the Judges Stand. Our drone team now includes Brian Montgomery, son of long-time H1 Unlimited announcer Steve Montgomery and long-time H1 contributor Dan Foard – the first person to fly an FAA-authorized drone over one of our events, in 2015. They bring a full complement of five DJI Mavic Pro 3 drones, along with hundreds of pounds of gear to each event to “fly” our referees to the prime viewing spots above each course.

The views from our drones are spectacular and allow a “camera on a pole” view from each turn on the racecourse, with an ultra-stable platform to view and record every heat. The video feed is sent from our pilot’s controllers directly to our video switcher, then to our Live Stream and the referee’s 35″ HDTV monitors equipped with DVR’s that allow them to immediately review their footage in order to make calls – most of the time before the boats even reach the dock!

Watch some of the drone footage in this Guntersville Final Heat review to get a feel for how much better the view is!

Society lives by rules and things are no different with H1 Unlimited. From what is allowed (and not allowed) on the boats to how the races are run and how the courses are set up, it’s all here.

THE RACES

Unlimited hydroplane racing has a long and colorful history, and the Hydroplane and Raceboat Museum is a great place to start learning more about the history of Unlimited hydroplane racing. The museum (also known as HARM) is located in Kent, WA and has an amazing collection of hydroplane memorabilia as well as many restored hydroplanes. Volunteers at the museum have restored some of Unlimited racing’s most beloved hulls: the 1955 Miss Thriftway , the 1957 Miss Wahoo, the 1962-65 Miss Bardahl, the 1973 Pay N’ Pak, the 1977 Atlas Van Lines “Blue Blaster” and the 1980 Miss Budweiser, among others.

At H1 Unlimited events in Tri-Cities, Seattle and others, exhibitions by some of the most famous hulls in Unlimited history are a part of the show. Learn more about the Museum’s mission by watching some of the videos below, and we wholeheartedly encourage you to visit the museum in person, and visit the websites we have included in the “Links” section below to learn more about the people, technology and the beautiful fast boats that make up the incredibly long and rich history of Unlimited hydroplane racing:

Boat racing in the Unites States has been going on since men first set sail, but organized powerboat racing began in the earliest parts of the 20th century and continues in a myriad of classes to the present day. The American Powerboat Association (APBA) is the sanctioning body for almost all forms of boat racing, but H1 Unlimited is the sanctioning body for all of our events except one.

Every year, Unlimited hydroplanes race for the oldest motorsports trophy in the United States: the APBA Gold Cup. The legacy of this trophy began in 1904, a full five years before what most consider to be the oldest motorsports trophy in the US: the Borg-Warner trophy given to the victor at the Indy 500. Except for a stretch during World War 2, the APBA Gold Cup has been awarded every year since 1904, and is the most prized trophy in Unlimited racing.

Unlimited hydroplanes have gone through five distinct periods of boat design and powerplant combinations: from the early part of the 20th century through the late 1940’s, conventional front engine, rear drive, deep “V” planing hulls that used a multitude of internal combustion engines were the standard and were not a huge break from then-current boat design norms. These designs stayed fairly static, with only incremental improvements.

In fact, the word “hydroplane” was not even associated with our class of boats until some pretty radical design changes were incorporated. In the early 1950’s, the second generation came in with a bang: the modern design standard of the round (or “shovel”) nose three-point hydroplane (a prop-riding boat with outboard sponsons that skipped on the water) began with what are widely regarded as the ancestors of modern racing hydroplanes: the Slo-Mo IV and Slo-Mo V, designed by Ted Jones of Seattle.

Almost all boats of the era were powered by then-plentiful WWII surplus aircraft engines and many colorful drivers were household names: Big-band leader Guy Lombardo, Chuck Thompson, “Wild” Bill Cantrell, Mira Slovak, Jack Regas and Bill Muncey among many others.

The U-1 Miss Bardahl – “The Checkerboard Comet” – was an example of state of the art hydroplane design in the late 1960’s. With Billy Schumacher driving, it won the championship in 1968. HARM photo:

In the design that dominated racing for almost twenty years, the driver sat behind the engine and the front of the boat had a rounded nose with the “sponsons” outboard of the center section, extending from the nose and ending about the back of the engine. The propeller on these boats was driven directly from the engine, so the engines were tilted at the same angle as the propeller shaft.

Unfortunately, these designs had disastrous consequences when the boats crashed, and many drivers were killed when the boats hit large swells, causing them to nose into the water at very high speeds. The worst day in the history of Unlimited racing occurred in 1966 at the Presidents Cup in Washington D.C. when three drivers: Don Wilson, Rex Manchester and Ron Musson were killed on the same day:

To try and combat these handling issues, some designers started experimenting with “cabover” designs, placing the driver ahead of the engine, changing the center of gravity to try and prevent these nose-first crashes. Even with more and more powerful engines, now capable of producing over 2,000 horsepower; the racing became marginally safer, but was still a very dangerous sport and drivers were still losing their lives.

Guaranteeing driver safety was a very slow process that had no clear-cut answer as the sport headed into the 1970’s. During the early 70’s, almost all consistent winners were still using aircraft power and the “conventional” round-nose hull.

The third generation of Unlimited hydroplane design came about with the popularity of the “pickle-fork”, or twin boom design familiar today that put the tips of the sponsons out in front of the center section.

Whether it was a conventional design or cabover, by the mid-70’s almost all winning Unlimiteds used this new design. Also, as surplus aircraft engines began getting more expensive in the early to mid1970’s, some teams began experimenting with now surplus turbine power plants that powered the Army’s helicopters.

The fourth generation of Unlimiteds began in 1973 when a group in Seattle launched the U-95, a twin turbine design that ultimately started a revolution that changed the sport. It utilized two turbine engines and was the modern cabover “pickle-fork” design.

As costs continued to climb for the V-12 engines, the turbines were now becoming more readily available and were reliably churning out more horsepower than the internal combustion engines and requiring far less maintenance over the course of a race season. The integration of turbines was a very slow process, taking many years to prove that they were a match for the aircraft engines, but as the sport moved into the next decade, the winning combination proved to be the turbine engined cabover design, and Unlimited racing in the 1980’s proved once and for all that the turbines were the way forward.

The U-95 was the predecessor to the turbine Unlimiteds you see today. HARM photo:

As the aerodynamic portion of race boat design was becoming better understood, Unlimiteds also began taking advantage of these aerodynamic principles: the overall shape of the boats allowed them to function almost like a wing, with the “tunnel” under the boat being fine-tuned to allow the boat to more effectively use the air itself to lift the boat. Sponson designs of the “pickle-fork” boats were increasingly helping the boats to skip on the water easier and turn better.

Various teams started experimenting with other aero devices like rear wings, trailing moveable flaps to control the air at the front of the boat, and finally the modern moveable canard wing you see on our modern hydroplanes.

Three dominant hydros of the 1970’s and 80’s: the 1973 Pay ‘n Pak, 1977 Atlas Van Lines “Blue Blaster” and the 1980 Miss Budweiser:

During every race, the driver and boat collect points for their qualifying performance and heat finishes. The boats that have accumulated the most points during the preliminary heats make it to the winner-take-all Final Heat. Note that we said “boats” – if multiple drivers drive the same boat and score points during an event, it’s the boat, not the driver that qualifies for the Final Heat. There is no guarantee that the boat that wins the Final Heat will come away with the most points.

Points are awarded for every session that features competition, such as qualifying, preliminary heats and the final heat. Points are not awarded for testing or exhibition runs.

For qualifying, the points break down like this:

- 1st Place qualifier receives 100 points

- 2nd Place: 80 points

- 3rd Place: 70 points

- 4th Place: 60 points

- 5th Place: 50 points

- 6th Place: 40 points

- Remaining boats that qualify above 130 MPH receive 30 points each.

- Boats that do not qualify or reach the 130 MPH threshold are awarded no points.

After each preliminary heat and the final heat, boats are awarded points based on how they finished. Each finishing place receives 75% of the points of the previous finisher :

- 1st Place: 400 points

- 2nd Place: 300 points

- 3rd Place: 225 points

- 4th Place: 169 points

- 5th Place: 127 points

- 6th Place: 95 points

- 7th Place: 71 points.

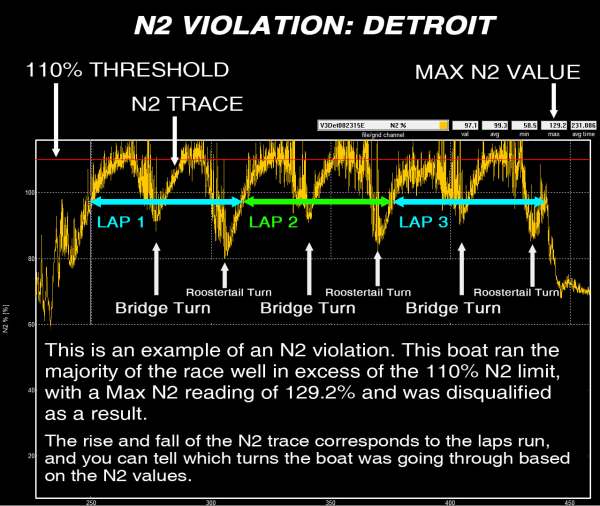

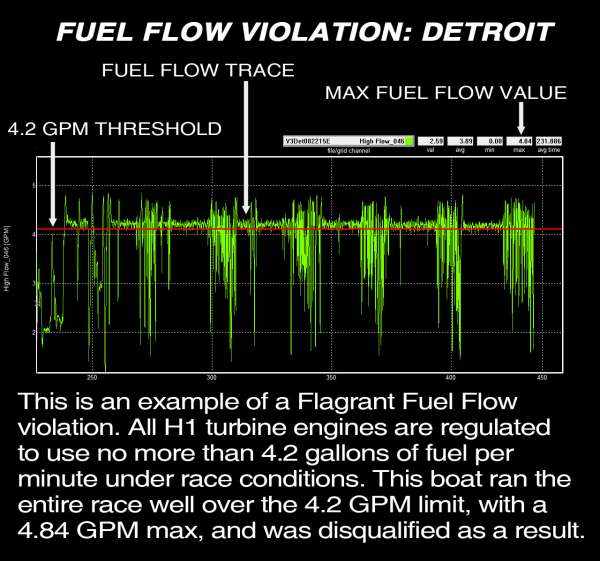

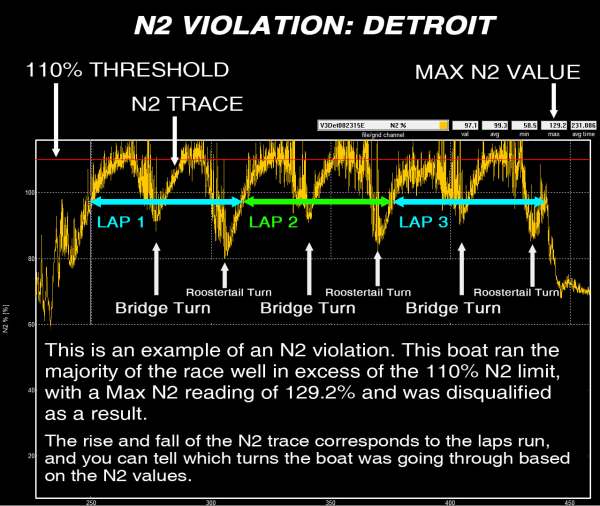

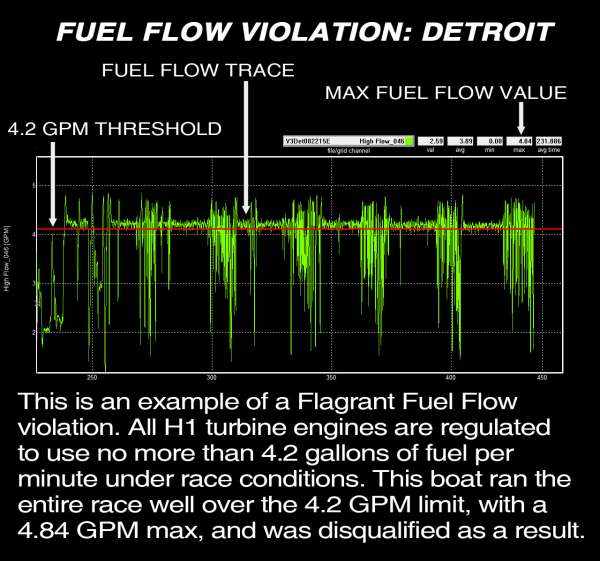

Points can be deducted for various rule infractions such as N2 or fuel violations, lane violations or unsportsmanlike conduct.

The winner of each race is determined by their finish in the Final Heat – points accumulated throughout the weekend have no bearing on their placing in the race – they only count toward the end of the season championship standings.

Points will count towards the National Champion Trophy for drivers and the National Champion “Martini & Rossi Trophy” for owners. Here again, there is no guarantee that the boat that wins the most races during the season will win the Championship.

For instance, the 2014 season saw J. Michael Kelly in the U-1 Graham Trucking win four of the six races, but Jimmy Shane in the U-6 Oberto took the Championship at the second to last heat of the season by virtue of accumulating more points.

Contrary to most other forms of motorsport that race on tracks with lanes or a starting grid where the cars will form up prior to the start and in their assigned starting positions, our drivers are free to try and grab any starting position they choose prior to the start, and that process starts with and is driven by a clock.

Each driver and crew chief will have their own clocks that they will synchronize EXACTLY to the official countdown clock so they can be as accurate as possible in timing their run up to the starting line, as the drivers will try to pass the start/finish line at EXACTLY 0:00 at full throttle – usually at around160MPH! Too soon, and they will have “jumped the gun” and will be issued a time or lap penalty, essentially ending their race. Considering that if the boat was traveling at 160MPH, it is covering 234 feet per second, so it shows just how critical that synchronization process is!

Prior to the start of each preliminary heat and winner-take all final, the official clock will count backwards starting at “10 to the 5” – this means that it is “ten minutes to the five minute gun”, or fifteen minutes to the start of the heat. This will be announced over the PA system but this callout is not super critical for the racers – this is when most boats will be lowered by crane into the water and drivers will be getting ready to enter the cockpit.

At “5 to the 5” (five minutes to the five minute gun), there will be another callout on the PA and usually in the driver’s earpieces from their radio man – and it is critical for them at this point to insure they are synchronized to the official clock. All drivers will be strapped into the boats with their safety gear in place and most will continue to check for exact synchronization with the official clock as each minute passes.

As the clock winds down to five minutes, there will be a ten-second count over the PA system. At five minutes, most drivers will fire their engines, leave the dock and enter the race course. The only exception to this is in Guntersville, where due to the length the boats must travel to enter the racecourse, they leave at six minutes.

At the one minute mark, or one minute “gun”, all boats must be up and running or they will be held at the dock and not allowed to take part in the race.

The 5 minute interval between the boats leaving the dock and arriving at the start is called the “milling period”, where each driver can go almost wherever they want on the race course to place themselves where they think they have the best shot at winning. What may look like a bunch of boats going slowly in circles is actually a VERY well thought-out process, and usually the subject of much planning prior to each heat.

Based on timing runs that each driver would have done in practice, he will know how long it takes him to pass the buoys on the course at a steady speed, so he will have a good idea of where he needs to be on the course and at what speed to allow him to make it to the start on time. However, these plans can definitely be thrown out the window based on lane position, positions of the other boats or other unforeseen circumstances that happen in the milling period.

You will likely see boats “cut the course” – moving from front stretch to back stretch and vice-versa through the infield at designated areas. This occurs when the driver is either out of place from where they need to be at a particular time, or it can be used to block another boat from grabbing an inside lane. However, there are areas inside the course where the rescue and judge boats are located, called the “DMZ” areas, and are clearly marked with buoys so the driver knows not to enter. If a driver does enter a DMZ, it is an immediate disqualification.

In the period before the start, all boats must maintain a minimum speed of 80 MPH as well, which is monitored via GPS on the onboard data logger and reviewed after each heat of racing. If it is discovered that the driver went below 80MPH for more than 5 seconds, they are disqualified. Look for the roostertail to be above the rear wing – if it drops below for any length of time, it’s a good indication the boat is going too slow and the driver may be in danger of that DSQ after his data is read.

Since the shortest way around the course is on the inside, Lane 1 is generally the preferred lane to start in, but the driver may definitely not want Lane 1 due to the way the boat is set up. If they have added taller gears in the gearbox or changed the propeller to maximize speed instead of acceleration, Lane 2 may be more to their advantage. Very rarely would any driver want to start from outside Lane 2. Since all boats were allowed to “fight for lanes” prior to the start, the driver that was the best at pre-race strategy usually ends up where they want to be and the rest of the field may have to run their race in a compromised lane choice.

Once lanes are established at the entrance to the turn prior to the start, all of the drivers will position themselves so that they reach the start/finish line as the official clock strikes 0:00, signifying the start of the race. Drivers do not want to “beat the clock” or they will be assessed a penalty, usually in the form of an additional lap or additional time added to their finishing time.

Keep an eye on any boats that are late to the start, ESPECIALLY if they have boats ahead of them on either side, as the run down to turn one can end up with the slower driver entering a “tunnel” formed by the roostertails of the faster boats, which is VERY powerful and can easily flip the boat or shred the canard, cowling and rear wing.

To sum up: if the driver and crew chief have done their pre-race planning, set up their boat correctly with the right gears and prop, synchronized their clocks, adhered to their timing marks, avoided other boats and grabbed their preferred lane, they MAY come away with a victory. If anything was overlooked or mistakes were made during the milling period, there are 4 or 5 other drivers that probably got it right and can take the win instead…

SAFETY SYSTEMS

By Dixon Smith

Question 1: Can a raceboat be made that will not flip?

Answer: Probably.

Question 2: Can that unflippable boat be a consistent winner?

Answer: Yes, but as one pundit said many years ago about another program, “when the Boeing Board of Directors changes the basic laws of Physics or gives us an endless budget, we can make this work.”

Real Answer: NO, not with current technology.

First a little history. Current race boats as we know them are generally called 3 point hydroplanes or prop-riders. This is because they ride on a small area at the back of each sponson and on the lower half of the propeller. The most famous first 3 pointer is the Slo Mo Shun IV. The Slo Mo IV was not the first 3 pointer, although it is the best known. There were a number of limited hydroplanes that were prop-riders prior to the Slo-Mo IV being built.

The first famous flip of a race boat occurred on Lake Washington in 1955 with the sister ship of the Slo-Mo IV, the Slo-Mo V, with Lou Fageol driving. The boat did a complete 360-degree flip and landed right side up, but with substantial damage. That happened over 50 years ago, and race boats are still flipping.

There have been several rather spectacular and famous flips in the unlimited class. In Pasco many years ago, the Pay ‘n Pak did a 720-degree flip, where it went around 2 times before hitting the water.

In San Diego in 1988, 2 boats, Circus Circus and the Miss Madison, did a side by side flip. A few years ago the Pico American Dream flipped in Seattle during a preliminary race heat, brought back to the pits upside down, repaired by the crew and ultimately won the final heat and the race.

There have been occasions where a unlimited race boat has done a 360-degree flip, landed right side up and continued running. When Steve David flipped the U-1 Oh Boy! Oberto in 2009 in Doha, the crew repaired the boat in time for the Final Heat, allowing Steve to take the 2009 High Points Championship!

Flips can injure the driver, but since the advent of the survival cell, very few drivers have been seriously injured and there have been no fatalities since the early 2000’s, when George Stratton was fatally inured in San Diego – mainly due to the lack of the HANS device (now mandatory for every driver).

Nearly all flips are disastrous to the boat – the least a hull can usually get away with is severe damage to the rear of the boat, and most boats that flip are very heavily damaged, requiring many hundreds of man-hours worth of repair before they can race again.

Corey Peabody flipped the U-9 Lynx Healthcare in Madison in 2022, just a week after winning the Gold Cup – doing extensive damage to the boat and taking it out of any further running in the 2022 season. The flip was so violent it ripped the entire right sponson off the boat!

Now, back to the questions.

First we need to understand a little about the physics of the problem. I will stay away from any equations, math or aerodynamic engineering stuff. I need to define a few things that will make this easier to understand.

Center of Gravity: The balance point of the boat. If you were to pick the boat up at only one point, and this was at the center of gravity, the boat would hang perfectly level. Without external forces, the boat will rotate around the center of gravity.

Center of Aerodynamic Lift: Some times called the center of pressure. If all of the aerodynamic lift were applied at the Center of Aerodynamic Lift, the effect on the boat would be the same as the real lift that the boat experiences.

Center of Hydrodynamic Lift: Same idea as the Center of Aerodynamic Lift, except the lift is from water, not air. These two are not in the same place.

Drag: All the stuff that keeps us from going fast. There is aerodynamic drag, drag from the air and hydrodynamic drag, drag from the water.

An interesting and important point is that water is about 800 times denser than air, or another way to say that is a bucket of water weighs about 800 times more than a bucket of air. If you don’t think air weighs anything or drag from air is not significant, hold your hand out the window of a car going 70 mph palm down, and then rotate your hand about 90 degrees and see what happens. Now think about that force, but multiplied 800 times, and you get an idea of the drag force from water.

Lift: To demonstrate aerodynamic lift, do the same experiment as above, hand out the window with palm down. Now rotate your hand a small amount in each direction and feel the upward or downward force. This is the lift force from the air. The same ratio of hydrodynamic drag to aerodynamic drag applies to lift. For a given speed and area, the lift from water is about 800 times the lift from air. That is why the sponson area in the water is very small compared to the total area of the boat.

Now, we need to have some stuff in the water, prop, rudder and skid fin. Anything else in the water is excess drag, and slows us down. So that is why to go fast, the boat needs to have as little sponson in the water as possible. The catch is how do we get as little sponson in the water as possible. Here is where those pesky laws of physics get in the way.

An arrow is a good example of something that works well aerodynamically. It has been developed over many thousands of years and has remained about the same for a long time, because it works. If you were to balance an arrow on your finger, you would find that the center of gravity is about 1/3 the distance back from the front. This is because the point on an arrow is somewhat heavy. The point being heavy is not only because it needs to be sharp and strong to penetrate a target or animal, but the weight up front makes the arrow more stable in flight.

Also, note the feathers are at the very back of the arrow. Remember the center of gravity is near the front, but the aerodynamic center is just in front of the feathers, very far back. Also, remember, per the definition of center of gravity, that the arrow, if disturbed in flight, will rotate about the center of gravity.

So if the arrow gets disturbed in flight and the front pitches up, it will rotate about the center of gravity, the tail will rotate down. When the tail rotates down, the feathers will increase lift and push the back up to re-level the arrow. If the nose of the arrow pitches down, the tail will rotate up, again around the center of gravity, and the feathers will push the tail down, again re-leveling the arrow. This is why an arrow flies straight and level. Arrows do not do 360-degree flips.

Well that sounds easy, let’s just design a boat like an arrow and make it stable. Here is where those pesky laws of physics and the practical world of boat racing don’t get along.

All raceboats have to be propelled by a water propeller. So, we need to keep the prop in the water. To do this, we need some significant weight on the prop. Most boats have about 1/3 of their weight on the prop and about 2/3 of their weight on the sponsons. To do this, means the center of gravity needs to be significantly behind the sponsons.

Remember that water drag is lots more than air drag, so we want to keep as much of the sponson out of the water as possible. The way this is done is to have the center of aerodynamic lift somewhat forward, to carry the sponsons, but not lift the prop out of the water. The result is the center of aerodynamic lift is forward of the center of gravity.

Two more pesky little problems rear their ugly heads about this time. The first is that lift goes up with speed, but much faster than speed. In fact, lift goes up with the square of speed. In other words, if speed increases 10% then lift increases 21%.

The other little problem is the center of lift is not in a fixed position, it moves around. The boat attitude, nose up or level, and height above the water both affect the position of the center of lift.

Here is the really bad news. As the boat pitches up, the overall lift on the boat increases. Remember the hand out the car window example and rotating your hand a small amount. Also, as the boat pitches up, the center of lift moves forward. Keep this in mind. Now, you say, but a lot of the boats now have canards that the driver can control.

For those who don’t know about canards, it is a movable wing, forward of the cockpit that the driver controls, typically with his left foot. With the canard, the driver has significant control of the overall aerodynamic lift on the boat.

Let’s put this all together and put the driver in the loop during a race. Remember, less sponson in the water makes us go faster. Also, both aerodynamic and hydrodynamic lift go up with speed, but faster than speed.

One last thing, the aerodynamic center of pressure moves forward when the boat pitches up. Race water, a bit rough, accelerating down the straight, need to go faster so use the canard to lift the sponsons to get them just touching the water. Speed is increasing, all is good. Turn coming up, look for the other boats, and the sponsons hit a wave that the driver didn’t see.

Because hydrodynamic lift is so strong and increases faster than boat speed, the boat pitches nose up. Two critical things happen when the boat pitches nose up: (1) the total lift on the boat increases very fast with pitch up, and (2) the center of lift moves forward.

If the driver is a little late changing the canard position, or the pitch up is so much that the canard cannot overcome the increased lift and center of pressure moving forward, then up we go. Initially the boat rotates around the prop, but as soon as the prop is out of the water, now the boat rotates around the center of gravity. This is why it looks like the boat hangs with the nose up for a short period of time, then quickly does some type of loop or roll.

Other things that can set the boat off and start the process of a flip are wind gusts and the boat entering a turn. The aerodynamic lift is a function of air speed, which is boat speed plus or minus wind. So on a gusty wind day, a gust of wind could increase the lift unexpectedly. This is a typical situation in San Diego, because of the local topography. Depending on boat design, entering a turn can significantly change the aerodynamic characteristics of a boat. Not all, but a significant percentage of flips occur at the entrance to a turn.

Back to the question of can a boat be designed to not flip and also be a winner? With the right stability control system, similar to what some fighter aircraft use, yes. For some classes of raceboats, these types of control systems are illegal at this time. Also, it will be very expensive to develop this type of system for a raceboat, well beyond the budget capabilities of most teams.

In conclusion, a good boat design and an experienced driver are the best insurance against flipping a boat. But, so far, nobody has built a boat that will not flip.

© Dixon Smith Dixon Smith was a long-time crew member on the Miss Budweiser hydroplane team. He began his racing career in the ‘60s on the crew of the Hawaii Kai III and Seattle Too. He refurbished the 1962-65 Miss Bardhal and drives it at vintage hydroplane exhibitions in Kennewick, Seattle and Chelan, WA.

By Roger Schaffer

The following essay was written in the 1990’s, but most of the principles outlined here are the same for current Unlimited designs.

A blowover is probably the most spectacular accident in motor racing. They have haunted our sport since the Slo-mo V flipped qualifying for the 1955 Gold Cup in Seattle. I witnessed this accident and have been interested in their cause ever since. Even though serious injuries and fatalities have been prevented by the enclosed cockpit, the high incidence of these accidents is a real cause for concern. By my count there have been at least 32 blowovers since the Slo-mo V flip. This last year alone there were six flips. The incidence of accidents has increased even though the boats have become much more technically sophisticated and many designs have been wind tunnel tested. What is going on here and how can the frequency of these accidents be reduced? This article examines the underlying cause of blowovers and makes some suggestions on how they can be reduced. Please don’t be put off by the technical terms. After this article you’ll be able to snow just about any hydro fan.

Lets face it, a hydroplane is basically a very low flying airplane. It makes sense that the same principles that apply to airplane stability can be used to understand blowovers. First, when is a hydro an airplane? Clearly when the aerodynamic lift is more than the weight of the boat, its an airplane (the rudder, skid fin and prop might still be in the water, but for all intents and purposes the hydroplane has become an airplane). Airplanes always take off when going into the wind and hydroplanes almost always blowover when going into the wind. This is because aerodynamic lift is due to the square of the relative wind speed over the wing. If the boat is doing 180 mph and hits a 20 mph wind gust it suddenly sees a 200 mph relative wind and the aerodynamic lift increases by 24 percent ((200/180)**2=1.24). In fact the speed at which a hydroplane becomes an airplane can be pretty accurately estimated by the formula: V = 45 x (W/S)**.5

In this formula V is the relative wind speed in miles per hour when the hydro is completely airborne. The term W/S is the wing loading and is simply the total weight of the boat divided by its deck area. The wing loading for current hydros is around 17 to 22 pounds per square foot. The square root of these values is between 4.1 and 4.7. This puts the blowover velocity at 185 to 210 miles per hour less any wind gusts. This formula tells us what we already know: light boats with lots of wing area fly (and will blowover if not stable) at lower speeds then heavier boats.

To keep from blowing over when in the airplane mode the hydro must have positive stability. This means that if the bow pitches up, even a little, there must be a “moment” produced by the boat that tends to pitch the bow back down. (A “moment” is simply a force that acts through a distance. A more common term for moment is “torque” and either term can be used. A wrench produces a moment or torque by applying a force multiplied by the length of the wrench.) If the moment produced by the boat is not strong enough, then the bow will continue to rotate up and over. What causes the stabilizing and the restoring moments? That is the essence of stability, but first some terms must be defined.

For safety, every airplane has a forward and aft limit on its center of gravity location. This location is established by the manufacturer and is based on the design of the airplane and FAA regulations. The “center of gravity” is the point where all the weight can be considered to be concentrated; it is the point where an object would balance if hung from a single cable. If a hydro is horizontal when lifted off its trailer, its center of gravity will be exactly between the forward and aft lifting points. If the boat points bow up when lifted, its center of gravity is aft of this mid- point. The aft most location of the center of gravity where an airplane is stable is called the “neutral point”.

For our purposes, the neutral point is the same as what engineers call the “aerodynamic center”. The aerodynamic center is the point where the aerodynamic lift can be considered to be concentrated and where the aerodynamic moment is constant. Sometimes you will here the term “center of pressure” used. It should not be confused with the “aerodynamic center”. The center of pressure is where all the aerodynamic lift can be considered to be concentrated and where there is no net aerodynamic moment. The problem is: the center of pressure moves allover the place depending on the angle of attack and height of the hydroplane. The neutral point does not move with angle of attack. Unfortunately, for most hydroplane configurations, it also changes with height above the water. Nevertheless, the neutral point is a better concept to deal with.

It is relatively straight forward for an aerodynamicist to determine the location of the neutral point for an airplane. This can be done using mathematical equations or by wind tunnel testing. However, it is very difficult to establish the neutral point for a hydroplane because of the effect of flying very close to the water. This so called “ground effect” greatly changes the way the air flows around a shape. It makes it hard to estimate the neutral point either analytically or by wind tunnel tests. To understand why ground effect causes this difficulty it is necessary to understand how the air flows around a hydroplane.

Air that hits a hydro between the sponsons either goes over or under the boat. The air that goes over the top will create a suction pressure due to the curvature of the shape, just like the upper surface of an airplane wing. This low pressure tends to be concentrated at about 25 percent of the length of the wing aft of the leading edge, just like an airplane. The air that goes under the boat behaves much different than an airplane due to the presence of the water surface. The bottom of a hydroplane is basically flat and slopes down from bow to stern.

You can better visualize the bottom shape of the boat by looking at the trailer when the boat has been removed. This bottom angle plus the sponsons and “air traps” along the sides form a scoop. This scoop stops or “stagnates” the air and generates the same type of pressure you feel if you cup your hand and hold it outside a car window. This pressure is pretty much the same all over the sloping part of the bottom of the boat. Therefore, the lift force from the underside of the boat is concentrated close to 50 percent of the distance back from the leading edge of the wing to where the slope ends.

The stability problem is largely due to the fact that the upper and lower surface lift forces act at different locations. The stability problem normally begins when the aerodynamic lift on the boat exceeds the weight of the boat. As shown above, this can easily happen when a head wind or gust is encountered. When the aerodynamic lift is greater than the weight there is a net upward force on the boat and the boat tends to move away from the surface of the water. Even a small upward movement allows more air to escape from the transom and sides of the bottom surface. This increased area for the air to escape is like a leak that allows the air bubble of stagnant air that the boat has been riding to escape more easily. The air pressure under the boat decreases while the air pressure on the upper surface does not change.

So a boat that was in perfect balance just an instant before hitting the gust now has a net bow up moment acting on it. This new torque is due to the change in lift on the under side of the boat and the fact that the upper and lower surface lift forces act at different locations. This new torque tends to rotate the bow up. If there is no other lifting surface (like a horizontal stabilizer) to produce a torque to counter balance the bow up torque, the boat will continue to rotate producing the classic blowover.

This explanation leads to the conclusion that boats without horizontal stabilizers will tend to blowover when ever the aerodynamic lift exceeds their weight. (The rudder and skid fin produce a moment which tends to keep the bow down, but only to a point.) Adding a horizontal stabilizer helps, but will not prevent a blowover. The restoring torque that the horizontal stabilizer produces is due to its surface area, distance from the center of gravity of the boat, and rate of change of its lift with angle of attack. If the center of gravity is aft of the neutral point the restoring torque will be insufficient to counter balance the destabilizing torque produced by the change in lower surface pressure. Even with a horizontal stabilizer, there will always be a center of gravity location where the boat will be unstable. Changing the angle of attack of the horizontal stabilizer does not move the neutral point; it only changes the amount of lift that it produces which changes the attitude of the boat which indirectly changes the blowover speed.

Most boats now have small wings that connect the sponsons and the fuselage. These “canards” have flaps along their trailing edge that the driver can control. These canards can change the attitude of the boat and can improve the stability of the boat if operated precisely by the driver. However, this is very difficult and because they produce a lifting force forward of the center of gravity they actually move the neutral point forward, closer to the center of gravity, which is destabilizing.

Several boats including this years T Plus have tried the two-wing (tandem wing) design. The advantage of this configuration is that the neutral point does not move forward when the height of the boat above the water increases; the neutral point remains fixed like on a conventional airplane flying out of ground effect. This makes it easier to estimate the location of the neutral point. However, it does not mean that two-wing boats can not blowover – they still can if the center of gravity is aft of the neutral point and the boat exceeds the blowover speed.

There are other mechanisms that can cause blowovers. The most common are the sudden lost of the rudder, skid fin or propeller blade. For example, the Miss KISW flipped in a practice run in Seattle this summer when its rudder came off. The rudder and skid fin produce a large amount of drag. Because this drag is below the center of gravity they tend to hold the bow of the boat down. When the rudder or skid fin suddenly come off this restoring moment is lost and the boat is left with a net aerodynamic moment that tends to pitch the bow up. Again, unless the center of gravity is far enough forward and the horizontal stabilizer is big enough, the boat will continue to rotate up and over.

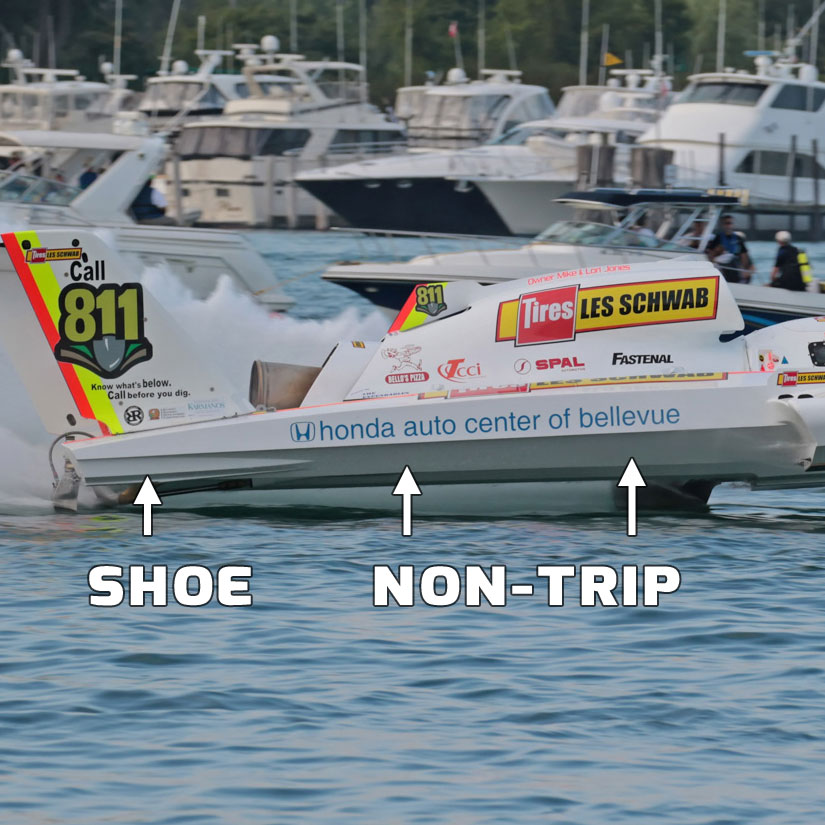

Until recently the loss of a propeller blade would often cause a blowover. The propeller produces a considerable amount of lift this is what holds the back end of the boat out of the water. Because this lift is well aft of the center of gravity the propeller lift tends to hold the bow down. The loss of a propeller blade, just like the loss of a skid fin or rudder, leaves the boat with a net bow up torque. If the boat is at or above its blowover speed it will flip unless there is sufficient restoring moment. Horizontal stabilizers and the “shoes” on the transom of most boats are helpful in producing this restoring moment and the loss of a propeller blade is much less of a problem then it once was.

Another situation that can cause a blowover is inadvertent movement of the center of gravity. If a boat gets a significant amount of water in its bilges and the water moves to the aft end of the boat, the center of gravity can move far enough to make the boat unstable. This was the cause of the flip of the 7 litre hydro Record 7 that almost killed Tommy Fults during a straight away record attempt in 1969. Boats should be designed to prevent the accumulation and movement of water inside the boat. Likewise, the fuel tanks should be at or aft of the center of gravity to prevent the center of gravity from moving aft when the fuel is burned off.

Is it possible to prevent blowovers? Probably not. However, it should be possible to reduce their frequency. The best solution would appear to be high quality wind tunnel testing to determine the location of the neutral point and its movement with height. Constant monitoring of the center of gravity to keep it forward of the neutral point by a safe margin would then be necessary. Wind tunnel testing is expensive and simulation of the ground effect is difficult. However, the cost of a blowover is also expensive, both in terms of damaged equipment and injuries to the driver.

Another option is to develop a design that automatically “bleeds off” excess air pressure to hold the aerodynamic lift to a value slightly less than the weight of the boat. If this could be done the hydroplane would never become an airplane.

Blowovers will likely remain a threat in hydroplane racing. However, they do not have to be a certainty, depending only on the next gust of wind. I hope this article helps in the understanding of these spectacular accidents.

In the previous section, you’ve seen what can happen when the boats flip, and that’s only one of the potential dangers to our boats and drivers.

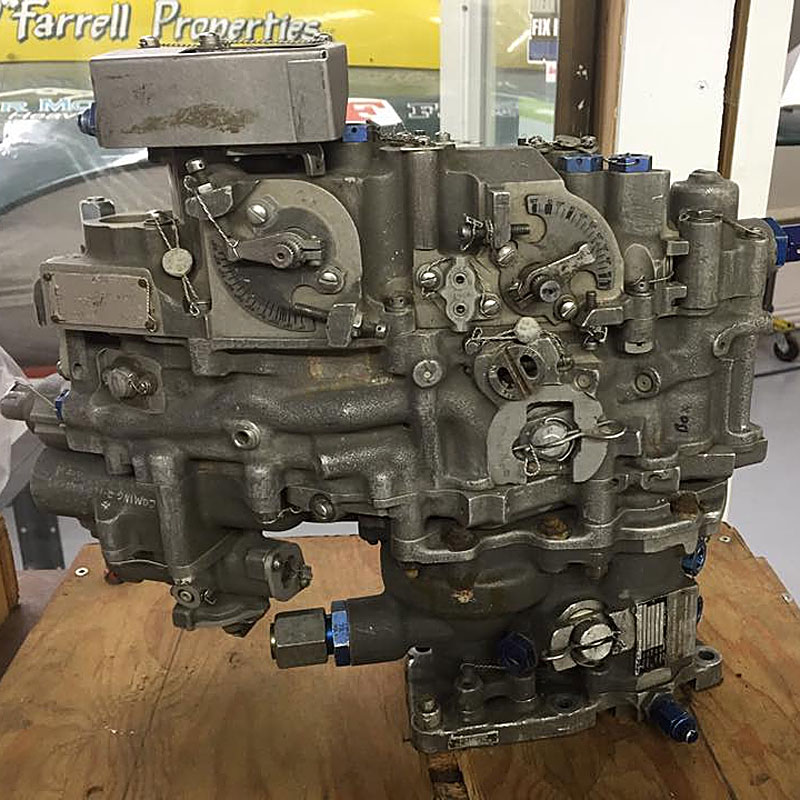

A single blade inside a turbine engine can fail, leaving $100,000 worth of scrap metal in it’s wake. Gearboxes can fail, turning $50,000 worth of precision machined parts into a pile of junk. A tiny crack on a propeller can suddenly cause a blade to break at 9,000 RPM, ripping the back half of the boat apart, potentially sending it to the bottom.

Unlimited hydroplanes are some of the most spectacular racing vehicles on the planet and put on an amazing show any time they are on the water. Unfortunately, in any machine traveling 200+ MPH on the water, there are a LOT of things that can go wrong.

COLLISIONS:

At the 2017 Gold Cup in Detroit, Bert Henderson spun in front of J. Michael Kelly’s U-12 Graham Trucking hydro, leaving Kelly nowhere to go but over the top of Henderson’s U-7 Spirit of Detroit. Fortunately, neither driver was injured in the accident.

At the 2013 UIM World Championship in Doha, Qatar, Tom Thompson’s U-11 Peters & May ran wide into Brian Perkins’ U-21 Snoqualmie Casino and ended up being catapulted up and over the top, into Doha Bay sideways at 130+ MPH. The impact completely destroyed the U-11 and severely damaged the U-21.

In one of the most dramatic examples of things going wrong in recent memory, the video below shows the final heat at the 2011 Madison Regatta from onboard the U-1 Oh Boy! Oberto. In the final, Dave Villwock in the U-96 Spirit of Qatar was leading Steve David in the U-1 Oh Boy! Oberto into turn 1 on lap 4 when Villwock hit a “hole” in the water, snapping the boat sideways directly into the path of David, and at over 100 MPH, there was no time to react.

Due to the tremendous strength of the structure in both boats and the safety features built in, Steve David suffered only some cracked ribs and Dave Villwock was unhurt in the accident. The U-96 raced the following weekend in Detroit, the U-1 was on the water later in the season.

Cockpit design has evolved over dozens of years of racing and has progressed to the current design, which is a more or less standardized “survival cell” for the driver.

The cell is framed in tubular steel and wrapped in composite and carbon fiber to make it as strong as possible, with a similarly constructed lid on top and an escape hatch with a Lexan window in the floor. There is a steel spar that spans between the sponsons and attaches to the front of the cockpit, forming an incredibly rigid structure that can withstand almost any impact.

The windshield is from an F-16 fighter jet and side windows are usually made of bulletproof Lexan.

Almost all modern hydroplanes use the newest cockpit design that incorporates a roof hatch that opens forward, but some older boats still use a hatch that hinges open to the side. These are being phased out due to the additional safety margin of the newer designs.

In the video below, in Heat 2A of the UIM World Championship in Doha, Qatar, Brian Perkins’ U-21 Snoqualmie Casino was run over by the U-11 Miss Peters & May of Tom Thompson. This dramatic video shows how the survival cell kept Perkins safe, allowing the U-11 to roll over the top of the boat rather than entering the cockpit. Perkins was uninjured in the incident and Thompson suffered a relatively minor arm injury.

Normal access to the cockpit is through the top hatch, but if a hydroplane flips and lands upside-down, the driver needs a way to get out. Since the roof hatch is now under water, it cannot be opened, so the only practical way for the driver to get out of the cockpit is through the escape hatch built into the floor.

All hydroplanes have this mandatory escape hatch, and it can be opened either by the driver from inside the cockpit or by rescue personnel from outside if the driver is incapacitated. The hatch covers and latches are standardized so all drivers and rescue personnel don’t have to memorize any boat’s particular arrangement in an emergency, which can cost valuable time in a recovery.

All current hydroplanes have escape hatches with a Lexan window that allows rescue personnel to see inside the cockpit prior to opening the hatch. Although flips are fairly infrequent, the hatches have been used a few times in the past decade and in every case, they performed as intended, allowing the driver to exit the (now underwater) cockpit quickly.

In the clip below, you see J. Michael Kelly flip the U-7 at the Columbia Cup in 2007, and very shortly after the boat has settled in the water, he opened the escape hatch and climbed out.

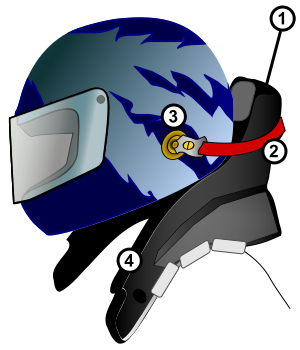

The driver wears a standard open-faced, rather than a closed-face helmet. This arrangement allows him to wear the air mask that provides an air supply and radio microphone, as well as attachment points for the required HANS device. Some drivers may also mount a visor or a fighter pilot style glare shield that flips down in front of their eyes instead of sunglasses to cut down on the considerable glare experienced at some race sites, particularly in the latter part of the day as the sun lowers on the horizon.

The air mask is the single most important piece of safety gear the driver has. In the event of a flip, the cockpit may fill with water and the air mask functions the same as a scuba diver’s regulator, providing air to the driver from an onboard scuba tank located behind the cockpit. This air supply is good for at least 15 minutes.

The mask also contains the microphone for the boat’s radio system, allowing the driver to communicate with his radio man. The microphone “talk” switch is normally a button located on the steering wheel and the radio speakers are contained in custom-fit earplugs that the driver may tape in place to keep them from being jarred loose. Both the air and radio systems have connectors that allow the mask to be connected and disconnected quickly.

Here Jimmy Shane tests the air mask for proper operation prior to testing – also note the earplugs:

Just like NASCAR, Indy Car and other top tier motorsports, our drivers wear a HANS device while driving their Unlimited hydroplanes.

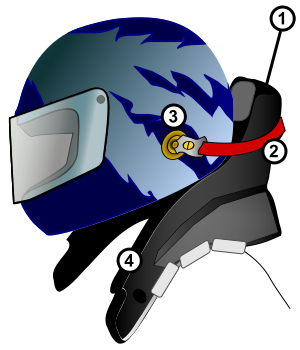

HANS stands for Head And Neck Support and was developed to greatly reduce the possibility of head and neck injury to the driver by helping to immobilize the head during violent crashes. The HANS device operates by fitting a support made from carbon fiber shaped in a “U” across the driver’s shoulders with the portion behind the driver’s head raised in order to hold tethers that attach to the helmet.

Once the driver is strapped in, the HANS device is held under the seatbelts, forming a solid anchor for the tethers.

1. HANS device, 2. Tether (one per side), 3. Helmet anchor (one per side), and 4. Shoulder support.

During a crash, the tethers limit the range of motion of the driver’s head, helping to eliminate the possibility of head and neck injury. Almost all boats also include a padded structure (head rest) on the right side of the seat that limits the motion of the driver’s head during hard cornering. Considering that our boats corner with 5+ G forces, this helps the driver keep his head upright.

The driving suit worn by H1 Unlimited drivers is of the same type you would see in any top tier motorsport – H1 rules require that the driver’s suit be fire retardant with tight fitting cuffs. Gloves and racing shoes complete the suit. A flotation vest or life jacket is also required, and this may be either under or over the driving suit.

THE DRIVER

To drive a modern Unlimited Hydroplane competitively requires years of experience, usually gained in lower classes of inboard or outboard racing, with many drivers having started racing at the minimum APBA-sanctioned age of 9 years old. Experience alone does not guarantee a driver will end up in one of these boats, but it almost always will determine whether or not they will be successful.

In order to even qualify to drive an Unlimited hydroplane, a driver must be a certified SCUBA diver, pass a capsule training program, pass a physical examination, pass a test on the rules and then prove they are capable of producing the requisite speed – a driver must run a minimum of 15 timed laps (during one season) under the observation of the Chief Referee, 2/3 of which need to be above 130 MPH in order to start in a race.

Once the driver qualifies, they must start five seconds behind the front row for their first two heats of racing, and even then can still be assigned an outside starting position if the Chief Referee deems them needing more experience.

Only when the Chief Referee “signs off” on a driver are they fully qualified to compete from any starting position In contrast to Unlimited racing 40-50 years ago, drivers enjoy longer careers mainly due to the advancements in all aspects of the safety systems built into in our boats. Today’s drivers are also younger on average than in years past, with most of our current drivers under 40 years of age.

For almost all of our drivers, H1 Unlimited is a small part of their annual racing schedule, and when not racing Unlimited hydroplanes they can usually be found racing other classes of boats at local events around their hometowns and in national events.

The video below shows J. Michael Kelly in the cockpit of the U-5 Graham Trucking during the Final Heat at the 2015 Gold Cup, showing how brutal a ride in a modern Unlimited hydroplane can be, regularly subjecting the driver to lateral loads over 5 G’s and instantaneous vertical loads approaching 10 G’s.

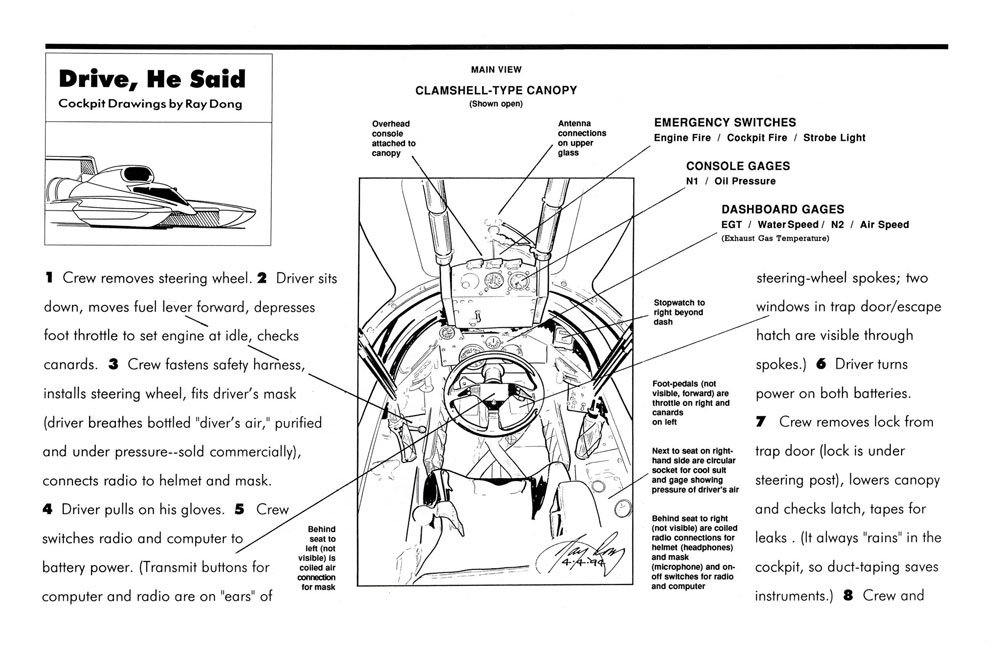

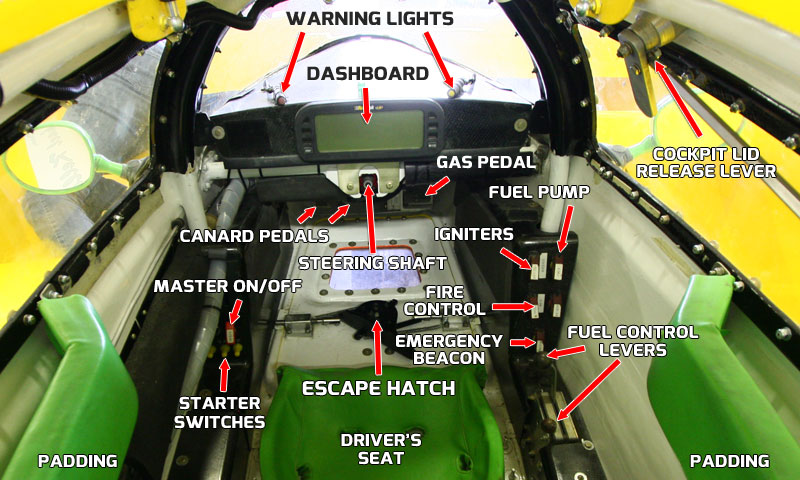

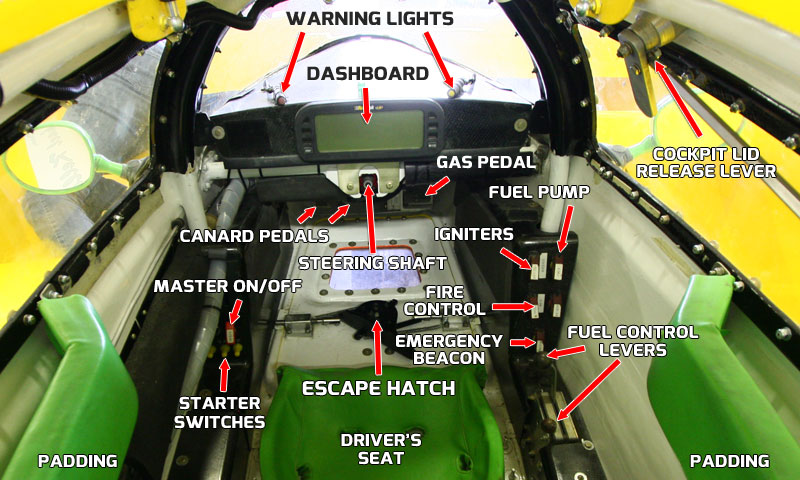

The cockpit of a modern unlimited hydroplane is a very cramped space. There is not much room for anything that is not necessary to run the boat. In fact, just to allow the driver to get in and out of the cockpit, the steering wheel must be removed.

To enter the cockpit, the lid on the top of the cockpit is hinged at the front and flips up to allow the driver to enter. There is a release lever that allows the driver to open the lid from the inside and this is duplicated outside the cockpit as well.

Once the driver is situated in his form fitted seat, he gets strapped in with a five-point harness system that has a single release to quickly unbuckle all of the belts at once in case of an emergency. The driver cannot tighten these belts himself – this must be done by crew members who are helping him get ready. The rule of thumb is that when you get them tight enough that you can’t breathe, tighten them some more…

On either side of his head are padded supports for his head that limits the amount his head can move during 5+ G turns. In conjunction with the mandatory HANS device, the driver is using the latest in safety technology.

His feet rest on three pedals: the one on the right is the gas pedal, just as you would find in your own vehicle, but the two left pedals operate the front canard system, allowing the driver to control the attitude of the front of the boat with his left foot – push down on one pedal to lower the rear edge of the canard and raise the nose of the boat, or push down the other pedal to raise the rear of the canard, pushing the front of the boat down into the water.

Under the driver’s legs is the escape hatch that is his only way out if the hydroplane ends up upside down. All drivers must pass a capsule training test in order to race an unlimited hydroplane.

On the dashboard is usually a display panel or gauges that give the driver information on the engine such as N2 RPM, exhaust gas temperature (EGT) or other parameters. Usually there are one or two lights on the dashboard as well – these warn the driver when they are approaching the upper N2 RPM limit.

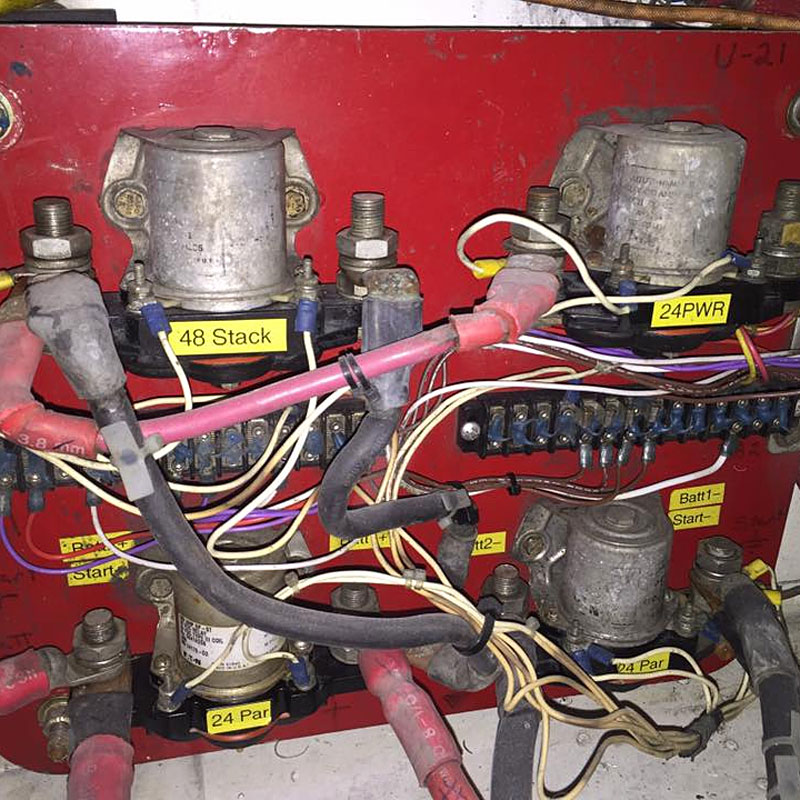

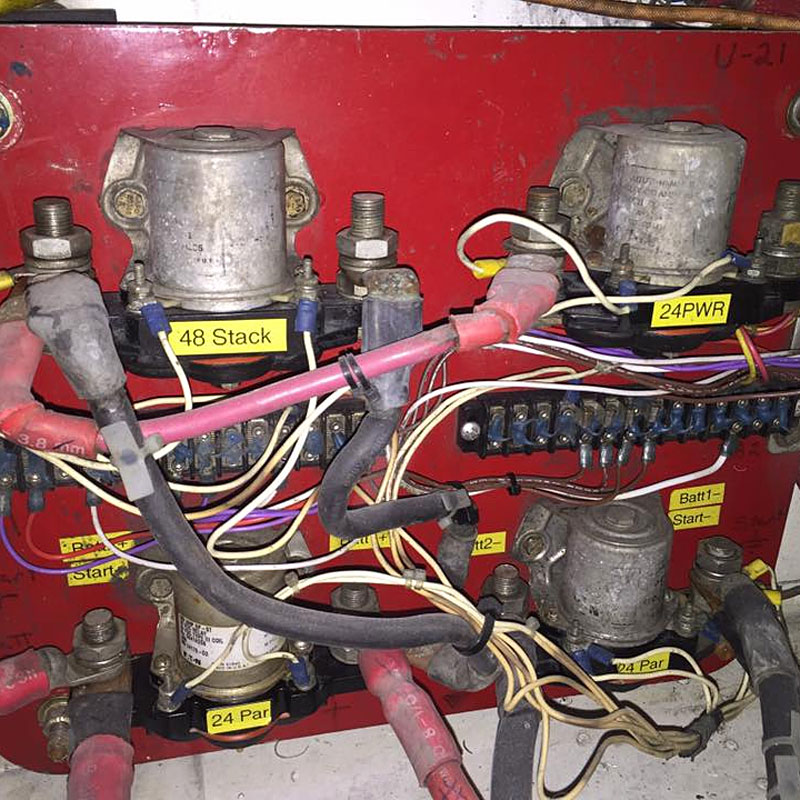

There are switches that control the flow of electricity to various items: a master on/off switch, emergency beacon, fuel pump, igniters, 24 and 48 V power for starting, and switches for the onboard Halon fire extinguisher system.

There are also levers that control the flow of fuel to the engine and since the engine will continue to run as long as it receives fuel, the adjustment on these levers is critical – this is the only way to turn off the engine once it has been started, so they have to be calibrated correctly.

The master switch for the electrical system and the fuel shutoff controls are duplicated on the outside of the cockpit as well so that rescue team members or crew can shut off all the systems on the hydroplane.

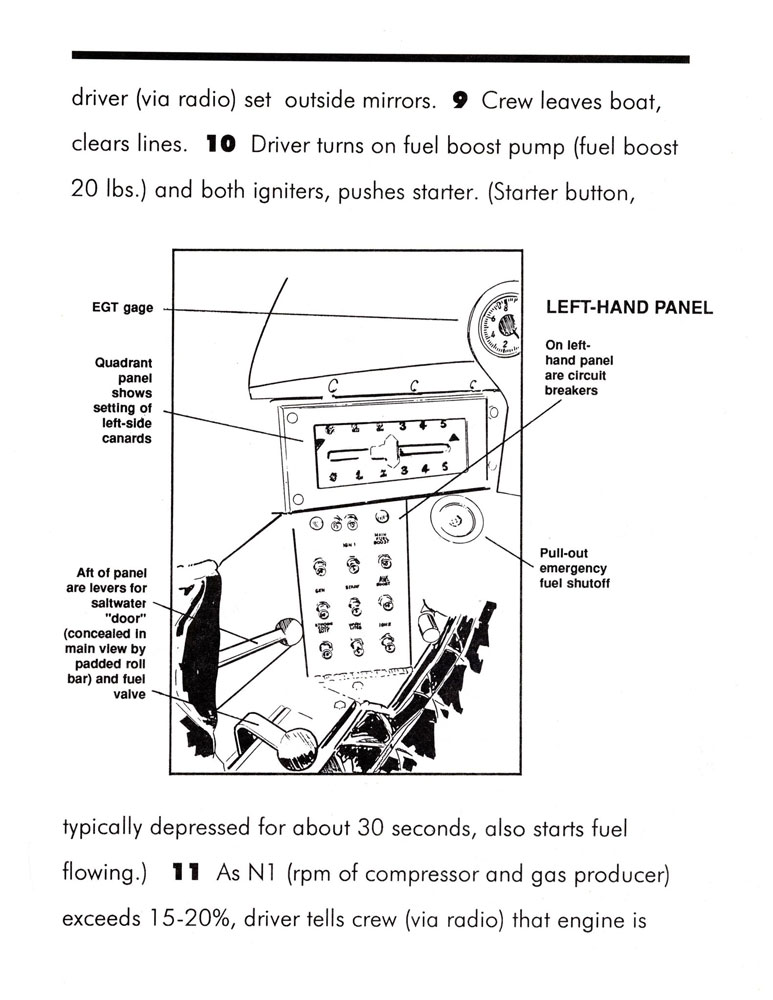

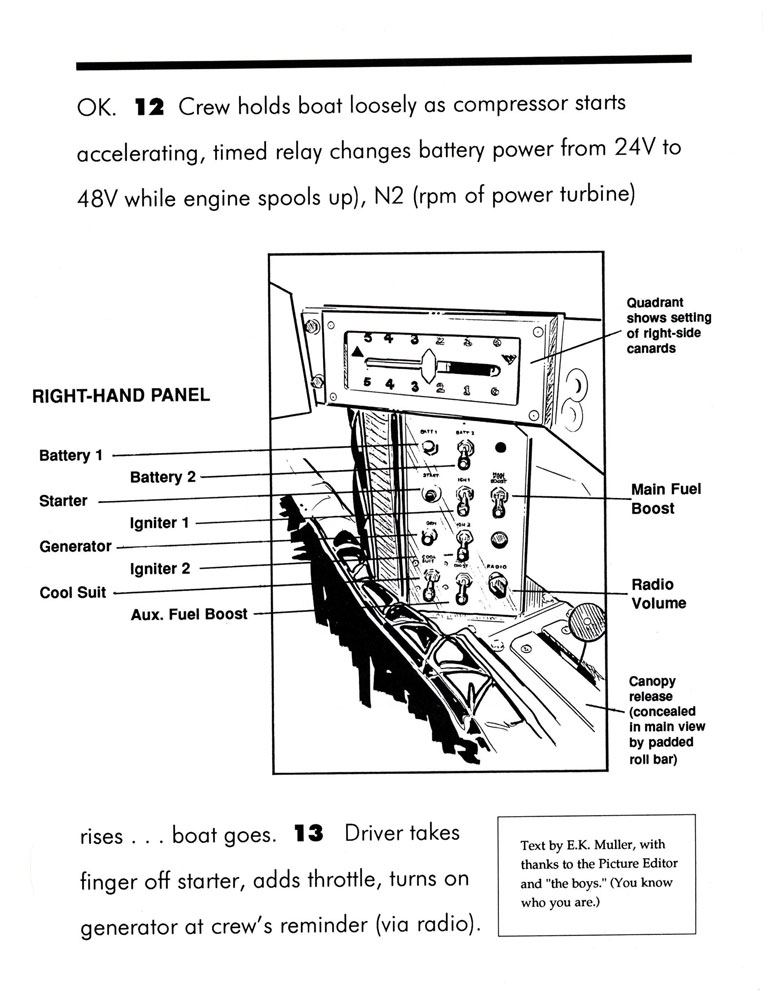

In the following infographic (courtesy of Ray Dong), you can follow the steps the driver and crew go through to get the driver ready and the boat started – there is a lot going on before the driver can even leave the dock!

THE TEAM

To get an Unlimited Hydroplane race-ready and competitive requires thousands of man-hours and tens of thousands of dollars to run each event. Without a well-oiled team to keep them afloat, these boats would be nothing more than fancy display pieces. A modern unlimited team requires workers to build (and rebuild) the boat, manufacture parts and modify boat systems, rebuild and install the engines and service the gear boxes, machine and care for the props, set up the wings and skidfins and program the computers and insure all the onboard electronics function. And that’s just what it takes to get the boat to run on the water!

Every team also needs a truck driver to haul the boat to every event and someone in charge of getting the rest of the crew on airplanes and into hotels during every event.

Once the team is assembled at the race site, they go to work getting the boat ready to run, and depending on the amount of damage their boat incurred at the previous race this may be a 2-3 hour process or it may take all day and most of the night! It’s no small task to bring along everything that could possibly be used or consumed during the course of a race weekend, but our teams are professionals that have been at it a long time.

Every team tries to come with what they need to be self-sustaining, but circumstances may throw their plans out the window! If a team needs help with spare parts, or their boat suffers damage that can’t be fixed with their own crew members in time for the next heat, it’s not at all unusual to see members of every team in the pits come together to “get it done” and get the boat back on the water!

Above: The U-11 Unlimited Racing Group team lends a bullnose to the Graham Trucking team in order to get them back on the water for the final heat in Seattle

Every Unlimited team has crew members that have been involved in racing boats for dozens of years, and most of their experience has come from doing multiple jobs on the various crews they have been part of. In other words, there is no “school” for becoming an Unlimited crew member – this is truly a sport where “on the job training” is about the only way to prepare someone for their position on the crew.

In addition, almost all teams have new crew members on the staff, and they will be picking up knowledge from the other crew members during every day at the shop, test event or race. If you ask around the pits, most crew members became involved through friends, relatives or just by “hanging around the shop” until someone gave them a broom and told them to clean up!

Most teams also have experts in the various disciplines: hull fabrication and repair, engines, gearboxes, propellers, wing and canards, cockpit systems, electronics, data and setup. These experts can come from the inside – through experience on Unlimited crews, or from the outside – turbine engine technicians from aerospace or propeller technicians from commercial propeller manufacturers, automotive technicians from car dealerships, etc. The route each individual may take to the sport may be different, but once they are here and demonstrate that they “know their stuff”, they will tend to stick around either on the teams that brought them in, or they will move to other teams that need their area of expertise.

Crew members that are knowledgeable and reliable are very valued and tend to be in high demand, so it’s not unusual to see a crew person stay in the sport for decades, while working for multiple teams. For instance, Tommy Alfano (currently on the U-8 Strong Racing crew) has been around Unlimited racing since the 90’s and in that span has collected almost two dozen crew shirts!

A Crew Chief on a modern Unlimited is equal parts mechanic, carbon fiber/fiberglass fabricator, welder, maintenance man, truck driver and mind reader. He is responsible for the off-season maintenance and improvements on the boat as well as all of the myriad things that go into making it race-ready at the race site. He may be the only full-time member of a hydroplane team, usually working year-round to repair and make new parts for the hydroplane.

An Unlimited Hydroplane is a very complex puzzle, and to get it just right requires the driver and Crew Chief to work together to fine-tune the machine – the Crew Chief may or may not also function as the driver’s radio man, but after every run the boat takes, the driver and Crew Chief will meet to discuss what can be done to make the boat faster or handle better.

Crew Chiefs come to their positions in various ways – some are crewmen that have worked their way up to the position, while some are ex-drivers. All have been involved in the sport for ten years or more and most Crew Chiefs in our teams today count their experience in decades. Mike Hanson (below) has been a driver, Crew Chief and boat builder for decades and is one of the most successful Crew Chiefs in the sport.

The radio man is the eyes and ears of the driver while he is on the course. The radio man will almost always be either the Crew Chief or another driver, and their job is to keep the driver abreast of critical information necessary to run the race. He will communicate timing marks, the positions of the other boats, lane information, penalty calls, etc. – all of which makes him almost as important as the driver in the overall scheme of the race.

All the radio men from every team racing in each heat are gathered together in the “corral”, which can be a spot on the pit tower, a man lift (or two) in the pits, or any area where they can have a good view of the course. An H1 Unlimited official is also present in the corral to pass along any calls that are made during the race to the radio man for the offending boat.

THE BOAT

A modern Unlimited Hydroplane is the world’s fastest circuit racing boat, capable of speeds in excess of 200 mph. It represents the product of over 100 years of evolution in race boat design and incorporates the most powerful engines, most advanced construction techniques and the best safety systems available in boat racing today.

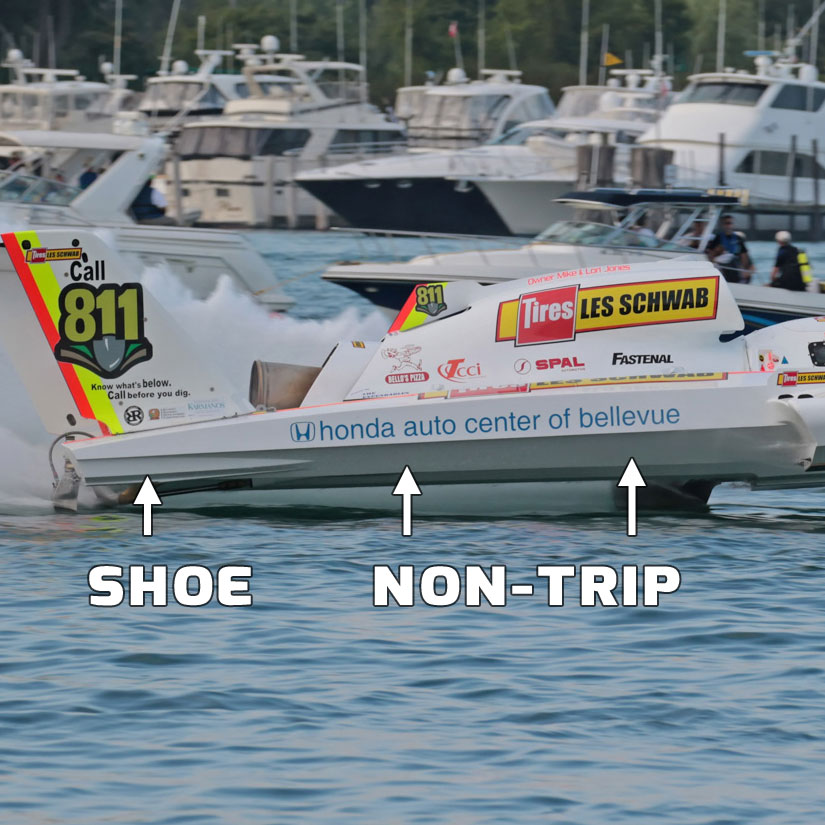

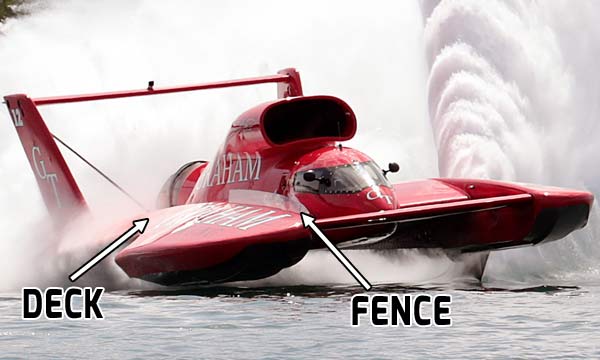

All Unlimited Hydroplanes are a “three point” design, meaning they are designed to only touch the water at three points when racing: at the rear of the two front “sponsons” (the projections of the hull in front of the driver cockpit), and the propeller at the rear of the boat. “Runners” under the sponsons and “shoes” at the rear of the boat are generally all that touch the water during race conditions.

A modern Unlimited is made of aluminum, steel, fiberglass, carbon fiber and graphite composites, and weighs a minimum of 6750 pounds in race trim. The boats are between 28 and 32 feet long, 12 to 14 1/2 feet wide and about seven feet from the bottom of the rudder to the top of the rear wing.

Driver safety is paramount in the design and operation of an Unlimited, so the boats have a number of systems designed to keep the driver safe in the case of an accident. The fully enclosed cockpit is the primary safety feature, incorporating a full interior roll cage that is bonded to the cockpit shell to maintain the integrity of the driver area. The windows are cut from the canopy of F-16 fighter jets, giving the driver ultimate protection, yet allowing him to see clearly.

Five point quick-release harnesses are used to keep the driver strapped into the seat and an escape hatch is built into the floor of the cockpit to allow the driver to escape if the hydroplane flips and lands upside down.

Every driver is required to wear a certified helmet and a HANS device for head and neck protection. He also wears a mask that incorporates an on-board air supply that allows him to breathe in case the cockpit fills with water, but also lets him communicate via the onboard radio.

Watch some of our drivers help explain what makes a hydroplane work:

Water is water, right? WRONG! Although we race on rivers, lakes and bays all over the world, our teams take a very different approach to racing on fresh water vs. salt water. This is due to the makeup of the water itself, the design of the boats and the power source – turbine or internal combustion engine.

Fresh water has no adverse effect on our boats or engines and there are no special precautions or setup changes necessary when we race on fresh water, but planning for salt water is dramatically different. When salt is dissolved in water, as it is in ocean water, that dissolved salt adds to the mass of the water and makes the water denser than it would be without salt. Because objects float better on a dense surface, they float better on salt water than fresh water. This means our boats and propellers act differently in salt water, so our teams have to take this difference into account when setting up the boats and choosing props. It also means that this dissolved salt is in every droplet of water that is ingested into our engines when we race.

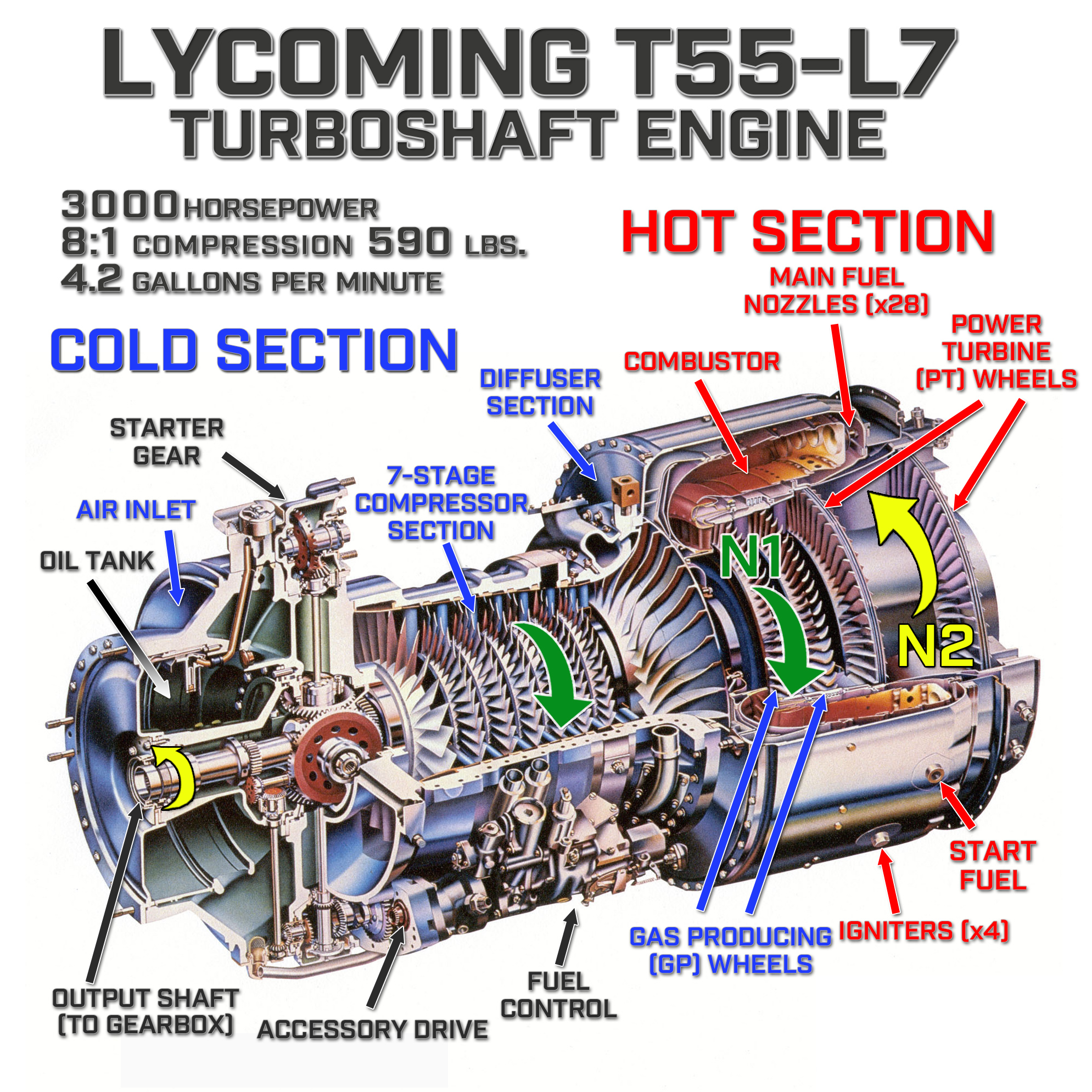

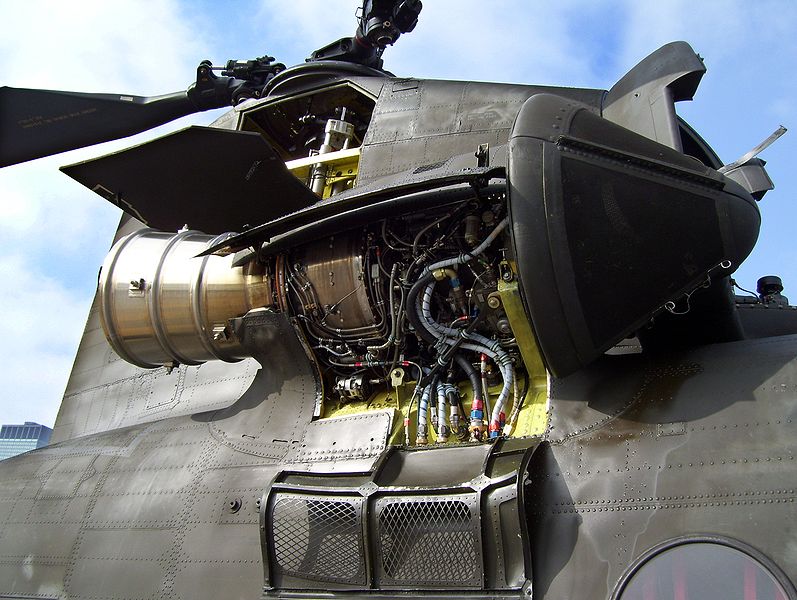

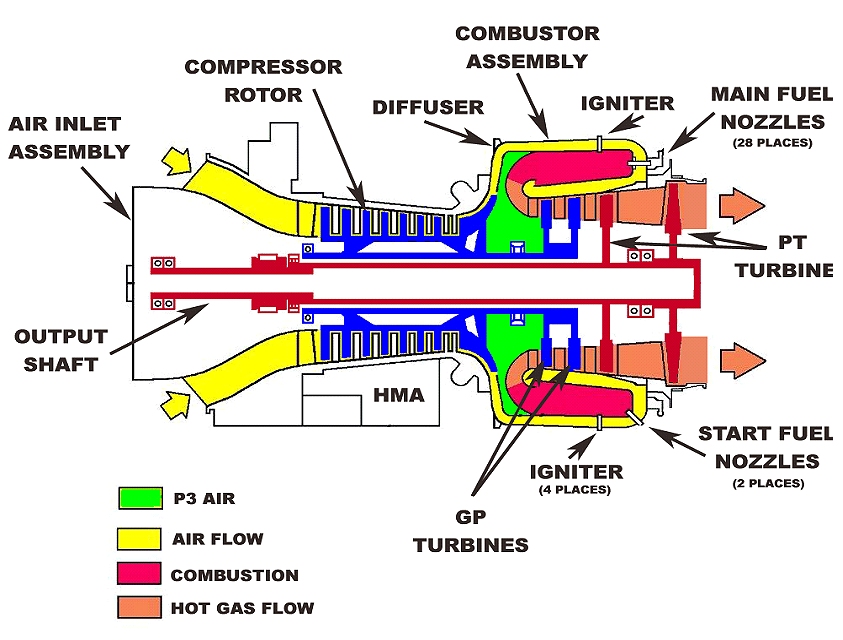

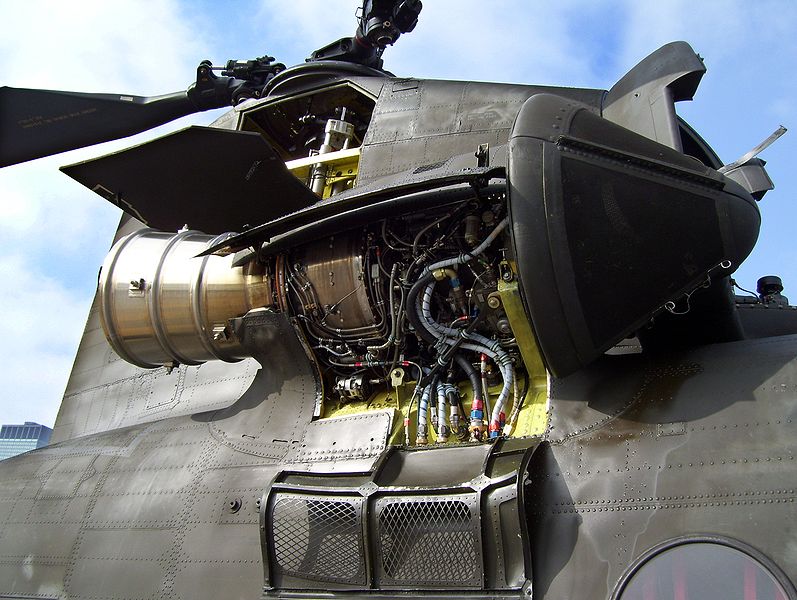

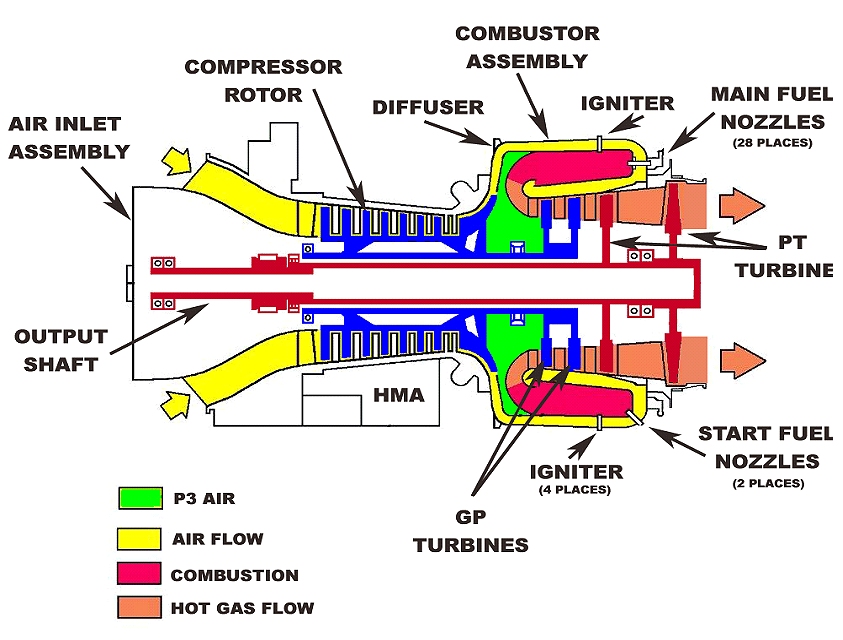

All boats that use the Lycoming T-55 L7 turbine engine have a MUCH different set of circumstances to contend with, and a little background on these engines helps put this difference into perspective: Turbine engines are actually very simple, and basically operate as a very large air pump: feed it fuel and air then add a spark and it will run very reliably and churn out huge horsepower until it runs out of fuel. Due to their design (and their original mission as the powerplant for the Army’s Chinook helicopters), they are able to take in large amounts of fresh water along with the air and still operate – as they would flying through a heavy rainstorm, for instance. The water simply gets vaporized in the combustion process and the engine continues to operate.

Although it’s possible to drown a turbine engine by ingesting extremely large amounts of fresh water, it’s almost unheard of to damage the engine as a result. This is definitely not the case in saltwater races! Even small amounts of salt water can cause catastrophic damage, so teams will do all they can to avoid getting saltwater into the engine.

When leaving the dock and getting on plane, all hydroplanes send up spray in front of the boat, and all turbine teams use a “snorkel” extension on the cowling and even moveable flaps in the snorkel to help prevent this spray from reaching the engine. Now also keep in mind that each boat leaves a 300 foot long wall of water behind it, and with 6 or 7 boats on the course you’ll quickly see that avoiding taking in water at a salt water race is not easy.

Once salt water enters the engine, the water gets vaporized, but the salt that is contained in the water remains and builds up on the turbine blades. Even though this buildup can be measured in thousandths of an inch, it effectively changes the compression ratio of the engine (normally around 8:1), causing “pre-ignition” that is very much like increasing the timing or compression ratio in an internal combustion engine, resulting in very large backfires that will shoot large flames out of the back of the engine. Left unchecked, it can do severe damage to the turbine blades and the engine itself.

All turbine teams will usually “de-salt” their engines with special chemicals and you may notice them spraying their hoses directly into the engine inlet when they run the engines on the trailer at salt water races – this helps break down the salt buildup on the turbine blades.

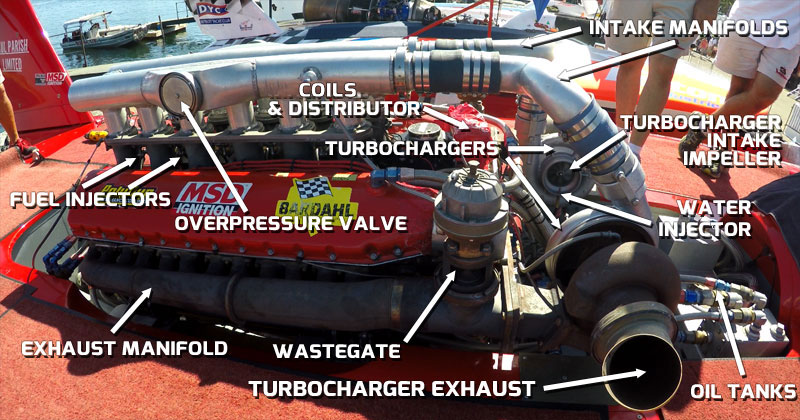

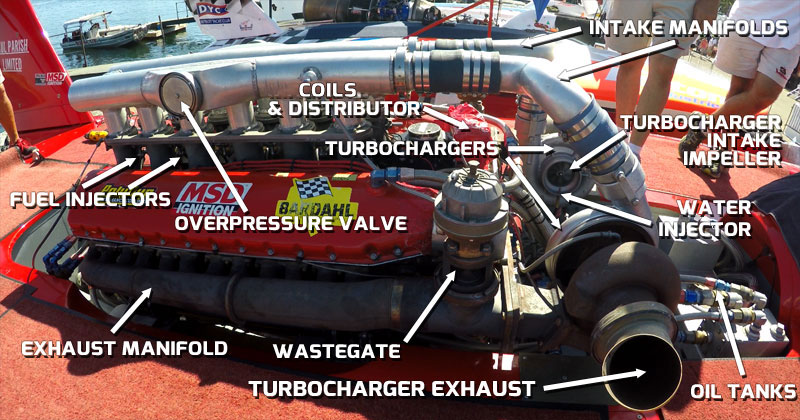

The twin-turbocharged V-12 Allison in the U-3 Cooper Racing entry doesn’t really care what water it’s racing on – it pumps out 3,000 HP whether it’s racing on fresh water or salt water, and this is the reason you will not see a cowl or “snorkel” on this boat during any race event – it doesn’t care what type of spray it’s breathing.

Additionally, due to the density of saltwater, there is more for the propeller to “push” against, which leads to more propelling force applied per revolution and consequently more speed. All current Unlimited competition speed records have been set on saltwater, with the current qualifying record of 173.384 mph set at San Diego, California in 1999 and the competition lap record of 166.221 mph being set at Pearl Harbor, Hawaii in 1992, both being set using unlimited fuel.

The large “cowling” behind the driver cockpit on all turbine-powered hydroplanes functions as an aerodynamic device and as a “scoop” to funnel intake air to the engine. The rear of the cowling is vented to allow for excess air to pass through so as not to trap air that would otherwise slow the boat down. All current Unlimited hydroplanes that use turbine engines have cowlings:

The U-3 Cooper Racing entry uses the V-12 Allison aircraft engine and is currently the only hydroplane that does not use a cowling:

All teams run only the large rear cowling during races run on fresh water lakes and rivers , but saltwater and turbine engines do not mix well at all! During saltwater races, an additional extension to the cowling (known as a “snorkel”) is used to prevent saltwater from being ingested into the turbine engine – shown below above the cockpit lid of the U-11 Miss Legend Yacht Transport. Some teams fit a moveable door to the front of the snorkel which helps prevent saltwater from being pulled into the engine during the time when the boat is getting on a plane and sending large plumes of water into the air in front of the boat.

J. Michael Kelly’s cowling came loose during the 2019 HomeStreet Bank Seafair Cup race, getting snagged on the rear wing. He finished the race with a cowling borrowed from the U-7 team.

The sponsons (sometimes called “Canoes” when molded in one piece that incorporates the sponson, chines and air trap) are the large outboard structures that the hydroplane rides on when getting up to speed, then skips on while running at full speed. The bottoms of the sponsons have what are called “Runners” built into them that have specific design details (generally stepped surfaces) that each team will modify in order to help the boat go faster.

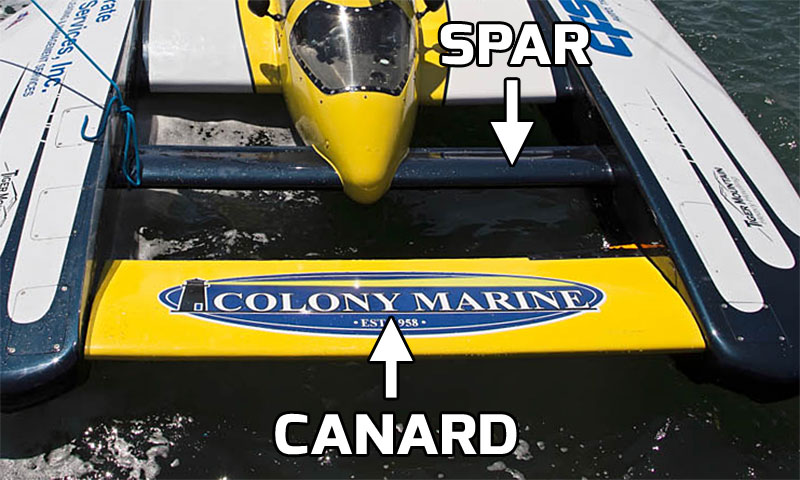

Sponson design and rigidity has a lot to do with the boat’s handling characteristics. The sponsons are glued or bolted to the “Center Section” of the boat (the main hull/engine bay/cockpit) and are further strengthened with the “Spar” – a steel beam that runs through the cockpit and ties the sponsons together. The spar is the non-moveable horizontal structure behind the canard.

All Unlimited hydroplanes have different designs for the left and right sponsons. Since the boats turn left and always present the right sponson to the outside of the turn, the right sponson is wider than the left and has a much gentler slope on its outside edge to help the boat skip over the waves. Most boats also have design details built into the inside edges at the front of the sponson that helps control the amount of water that splashes onto the windshield when running at lower speeds. These details are not so important now that the minimum running speed has been increased to 80 MPH.

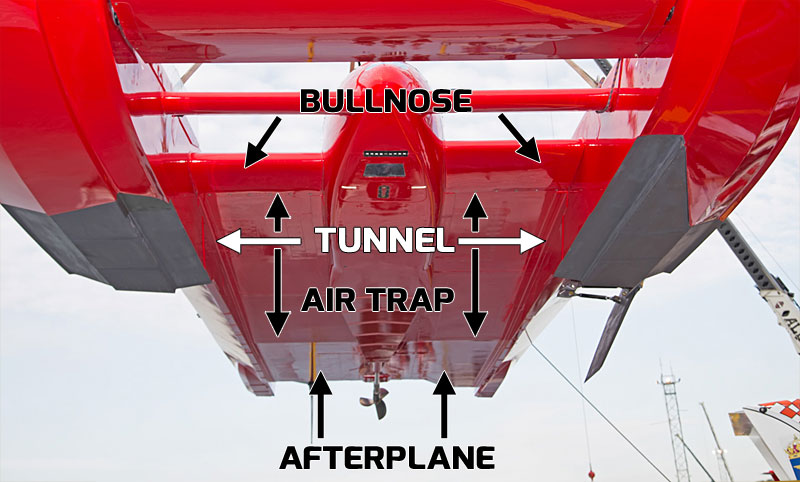

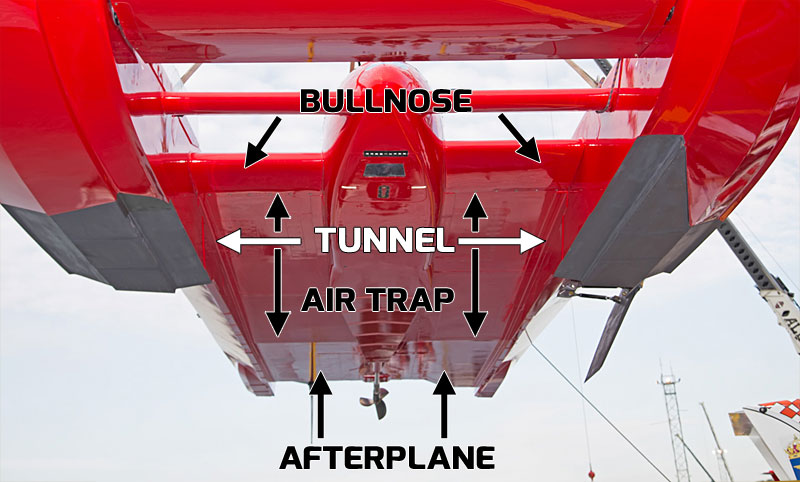

All modern Unlimited Hydroplanes incorporate a “Tunnel” under the boat that traps air as the boat reaches racing speeds, using the air pressure trapped in the tunnel to lift the boat and allowing it to reduce drag by flying across the water rather than plowing through it.

The tunnel is formed by the inside edges of the sponsons and incorporates an “Air Trap” that has a varying contour that is taller at the front than at the back. The Air Trap compresses the air as it travels under the boat and provides lift on the hull.

The forward edges of the Air Trap have what are called “Bullnoses” on each side of the cockpit that can be changed, with different contours or lengths to further fine-tune the amount of air that is fed to the Air Trap to help adjust the center of pressure.

The flat area aft of the Air Trap is called the “Afterplane”. The Tunnel width and length, along with the Air Trap angle and other design details all help contribute to the overall handling characteristics of the boat and are unique to each hull – what works on one design is certainly not guaranteed to work on another.

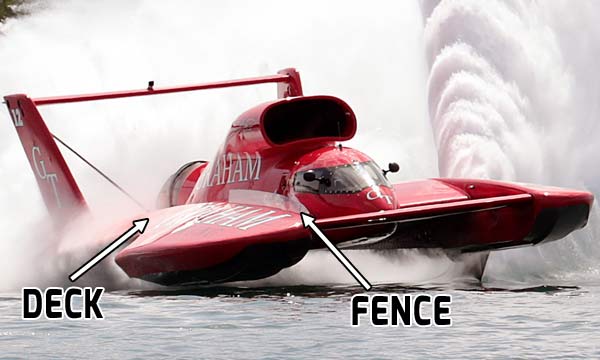

The deck is a structural component of the boat that forms the top of the hydroplane and is generally made of a sandwich of various composite materials. Over the course of the season, it is not uncommon for the deck to crack or split due to the tremendous forces exerted on the boat, and if this becomes severe or if there are cracks in critical areas, the team will replace it in the offseason.

The deck has a multitude of hatches (generally made from the pieces of aluminum) that give access to the various components that are located within the hull, such as steering cables, rudder linkage, fuel tank, fuel and cooling lines and other items.

The deck also has a gentle convex curve from front to back, which if looking at the hydroplane from the side, forms the upper surface of a wing with the bottom of the hydroplane basically flat. This helps generate aerodynamic lift.

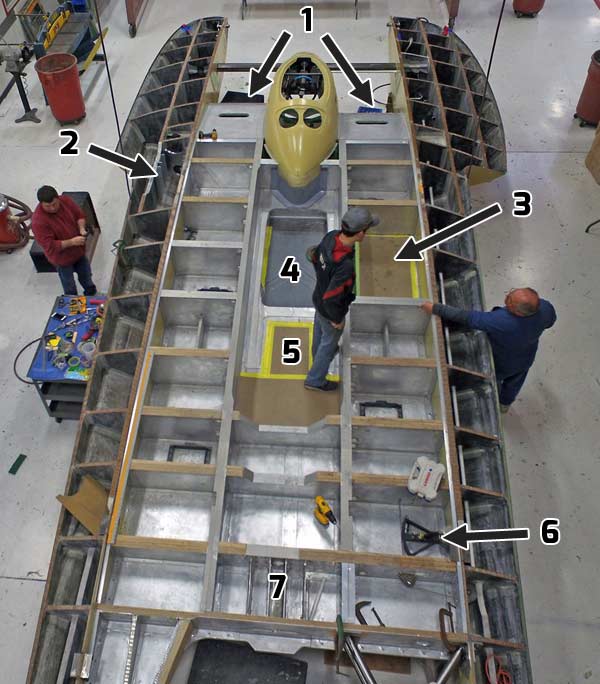

As the new for 2018 Miss Madison was taking shape, we took this image that shows what lies beneath the deck of a modern unlimited hydroplane. The entire structure is crisscrossed every 18-24″ with composite or aluminum sandwich braces in order to make the entire structure as rigid as possible, and some areas will have more structure added than is shown here.

Some highlights:

1: Bullnoses – Here you can see the left and right bullnoses are different lengths, which will be further fine-tuned with the additional of the outer bullnose shells. These will help determine how much air the boat “scoops” to feed the air trap underneath the boat.

2: Skidfin box – In this image, the additional braces that will make up the skidfin box are not yet added. When the boat is done, this area will be full of high-strength braces and brackets in order to withstand the extreme stresses the hydro will endure when cornering.

3: Fuel cell: The fuel cell will hold up to 50 gallons of Jet A in a rubber bladder full of material designed to minimize sloshing.

4: Engine bay: The engine and gearbox will fill this area, and will be mounted as low as possible in the hull to lower the center of gravity of the boat.

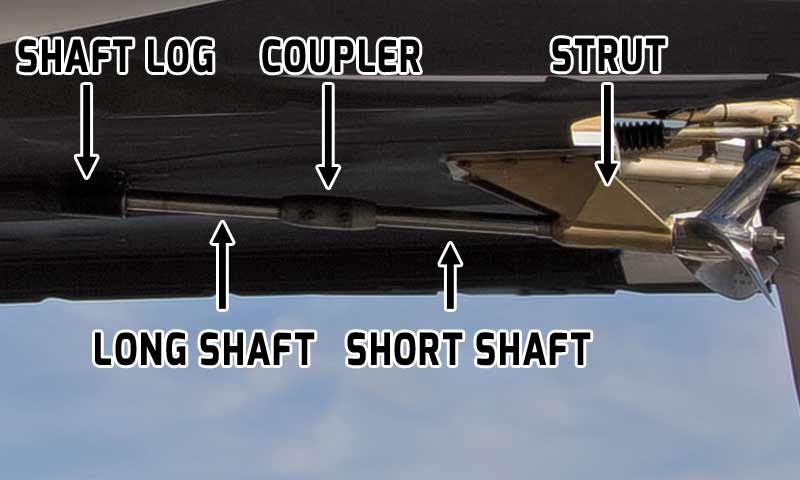

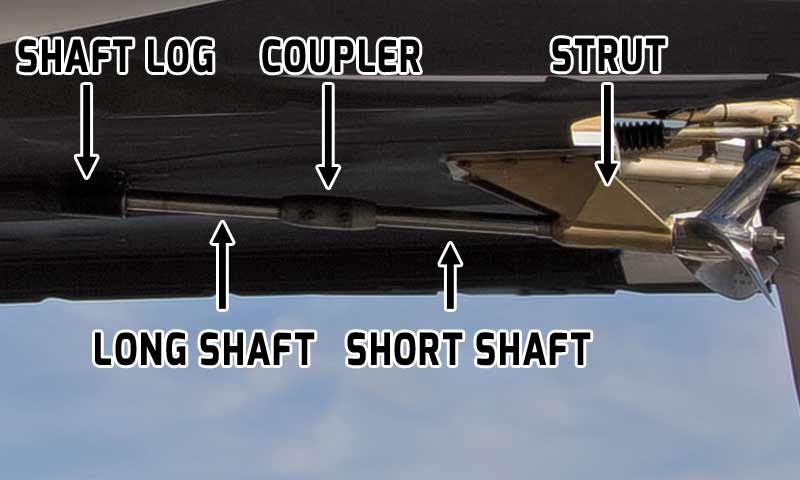

5: Shaft log: The shaft log is where the long shaft exits the hull. It transmits the output of the gearbox to the propeller.

6: Rudder quadrant: The steering cables engage the rudder quadrant that transmits steering input to the rudder.

7: Strut: The strut holds the propeller shaft (short shaft) and is mounted in this area underneath the boat. In order to keep the strut as solid as possible, the area it mounts to has additional bracing installed.